Regency

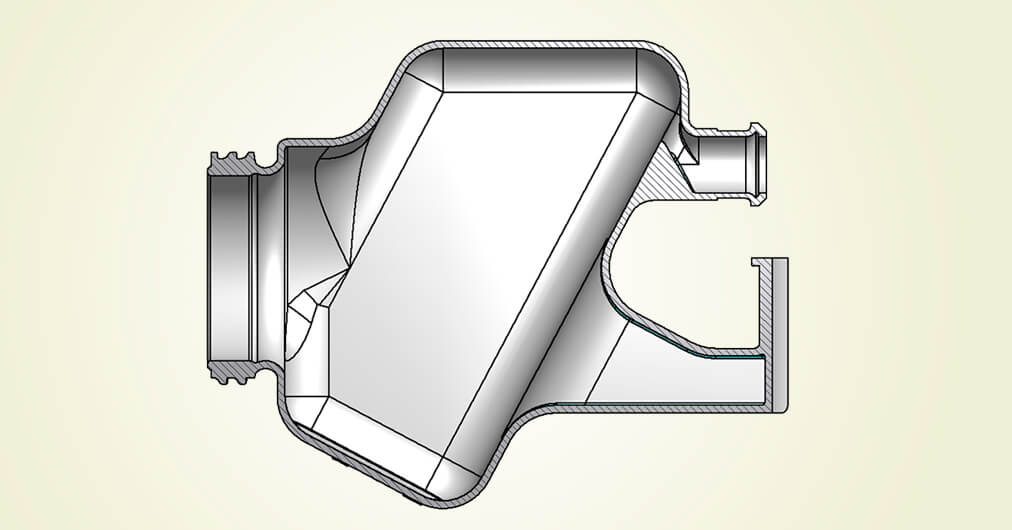

BLOW MOLDING MATERIALS

Unlike our competitors, we work with a broad range of materials, giving you more options and flexibility. We leverage our extensive material expertise to optimize your design and enhance product performance.

We have the expertise to not only mold your part, but assist with the material selection process to ensure your parts’ optimal performance and identify opportunities to drive cost out of your product.

Enhanced material properties

- Glass or Talc Filled

- UV-Additive

Enhanced surface finishes

- Class A – Color Matched

- Graining

Most Commonly Recommended Blow Molding Materials

Nylon (PA)

- Durable, temperature resistant

- Suitable for underhood and structural applications

TPE, TPR, and TPO

- Flexible materials

- Suitable for soft-touch and sealing applications

Polyethylene (HDPE, MDPE, LDPE)

- Cold-impact and chemical resistance

- Suitable for fluid reservoirs and fuel tanks

Polypropylene (PP)

- More heat resistant than polyethylene

- Suitable for underhood applications

case study

Converting a Rotomolded DEF Tank to Blow Molding

Discover how blow molding helped a Tier 1 supplier of custom fluid management consolidated their supply chain, increase efficiency, and reduce costs while meeting all production and performance requirements.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

An Insider’s Guide to Plastic Process & Material Selection

It’s easy to under-design or over-engineer a plastic part. Whether you’re designing from scratch or converting from metal to plastic, there are a number of constraints you need to consider for each process and material option. Our engineers created this guide to help.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields