GPI, GT Plastics, Sierra, GPM

CUSTOM PLASTIC EXTRUSION APPLICATIONS

There are countless applications for plastic extrusions, and we have the expertise to meet the most demanding ones. We specialize in engineering and manufacturing plastic extrusion products for OEMs and Tier 1 suppliers throughout the automotive, building and construction, lawn and garden, and consumer industries. Yep, we’re just about everywhere.

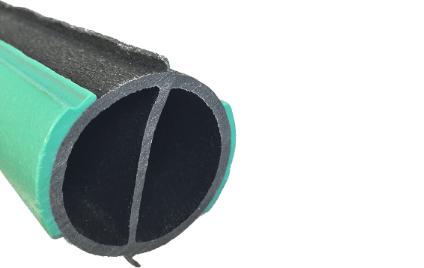

Extruded Seals

Our thermoplastic extruded seals are an excellent alternative to rubber, offering optimal performance in sealing and weatherstripping applications. We specialize in processing the most advanced plastic compounds available today, enabling us to tackle even the most demanding sealing challenges.

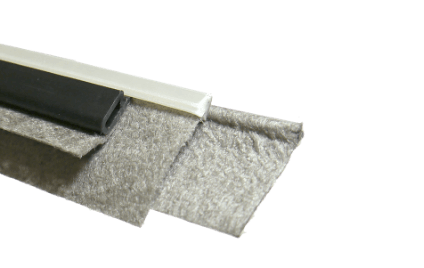

Structural

Engineers rely on us every day to replace conventional metal extrusions with durable and lightweight structural plastic extrusions. Our skilled team is well-versed in optimizing designs and materials to meet the rigorous requirements of structural applications while simultaneously lowering cost and reducing lead times.

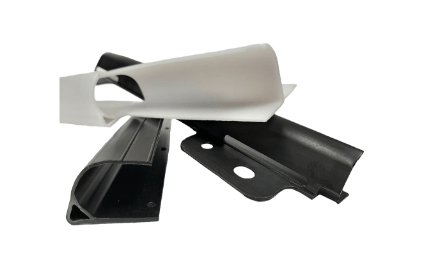

Seating

Two-thirds of the seating in North American automobiles rely on our precision profile extrusions. We are specialists in J & Arrow retainers, stiffeners, and beaded duon tie-downs that add ease of assembly and occupant comfort to contemporary seating manufacturing and design.

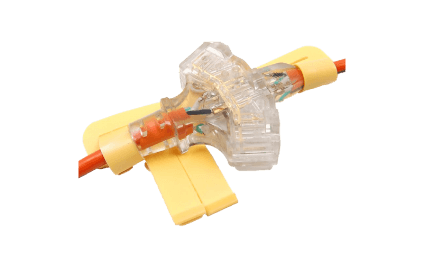

Electrical

As electrical applications grow, organizing the resulting mass of wire and cables becomes a challenge. We specialize in producing custom plastic extrusions such as the channels, harnesses, locking closures, and overlap closures that keep electrical components in their place.

Safety

Safety components must perform flawlessly under extreme conditions. Our extrusions undergo stringent performance testing before shipment, including airbag deployment testing at temperatures as low as -40⁰ Celsius. You can count on us for safety-critical applications.

Other

With decades of experience developing custom plastic extrusion profiles, we have the engineering, rapid prototyping, and in-house tooling capabilities to help develop the ideal profile for nearly any high-volume application. Let us bring your vision to life.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

PLASTIC EXTRUSION DESIGN GUIDE

Is your extrusion design optimized to meet the constraints of the extrusion process? This free guide offers a solid foundation in the requirements for successful extrusion design. Created by engineers for engineers, and based on decades of extrusion development and manufacturing experience.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields