GPI, GT Plastics, Sierra, GPM

IN-HOUSE TOOLING DESIGN & BUILD

We take pride in our ability to design and build high-quality tooling in-house. We have the engineering resources and expertise to get the job done so you can enjoy shorter lead times and fewer headaches.

IN-HOUSE TOOLING FOR PLASTIC EXTRUSION PROFILES

Our team has built full tooling systems for over 7,000 plastic extrusion profiles throughout the years. This includes all the tooling necessary from prototyping to quality assurance.

Prototype and Production Extrusion Dies

Our skilled team of tooling experts excels in the design and fabrication of both prototype and production dies for plastic extrusion profiles. We understand the importance of precision and efficiency in die design, ensuring optimal material flow and consistent profile dimensions.

Trim and Fabrication Tools

For the finishing touches on your extruded profiles, we have the capability to create custom trim and fabrication tools. These tools enable us to achieve clean and precise cuts, ensuring the highest quality of the final product.

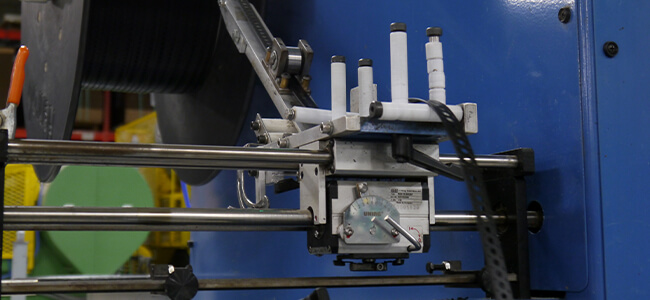

Fixtures and Gauges

To guarantee accuracy and consistency, we develop fixtures and gauges that aid in the manufacturing process. These tools allow for precise positioning, alignment, and measurement of your plastic extrusion profiles, ensuring the adherence to strict quality standards.

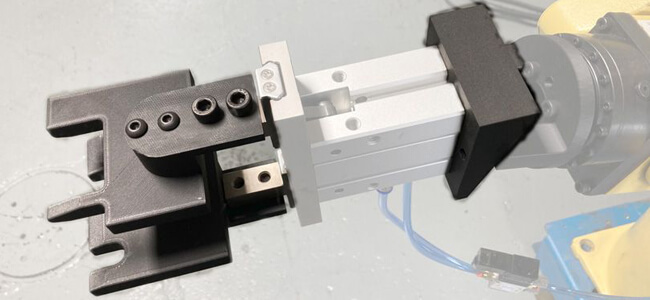

3D Printed Tooling

As part of our commitment to innovation, we have integrated 3D printing technology into our in-house tooling process. This technology allows for greater design flexibility, enabling us to quickly adapt and optimize tooling designs based on specific project requirements. This agility and versatility contribute to faster turnaround times and improved overall efficiency in the production of your plastic extrusion profile.

BENEFITS OF IN-HOUSE TOOLING

By designing and building our tooling in-house, we have complete control over the entire process, from concept to completion. This not only ensures superior quality but also provides significant benefits to our customers.

Lower Tooling Costs

Our in-house tooling capabilities allow us to optimize the manufacturing process, resulting in lower tooling costs for your plastic extrusion profile. By eliminating the need for third-party tooling suppliers, we can offer competitive pricing without compromising on quality.

Reduced Lead Times

Time is of the essence in the fast-paced manufacturing world, and we understand the importance of meeting deadlines. With our in-house tooling design and build capabilities, we can significantly reduce lead times, ensuring timely delivery of your projects.

WHY GEMINI?

We strive for excellence in every aspect of our business. Our in-house tooling capabilities are a testament to our commitment to providing our customers with the highest quality products, cost-effective solutions, and efficient services. Partner with us for your plastic extrusion profile needs, and experience the advantages of our in-house tooling design and build expertise.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

PLASTIC EXTRUSION DESIGN GUIDE

Is your extrusion design optimized to meet the constraints of the extrusion process? This free guide offers a solid foundation in the requirements for successful extrusion design. Created by engineers for engineers, and based on decades of extrusion development and manufacturing experience.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields