GPI, GT Plastics, Sierra, GPM

END-TO-END PLASTIC EXTRUSION MANUFACTURING EXPERTISE

Our comprehensive lineup of plastic extrusion manufacturing processes allow us to produce finished extrusions completely in-house. From tooling design and build to extrusion and secondary processing, we optimize the entire process to add value and drive cost out.

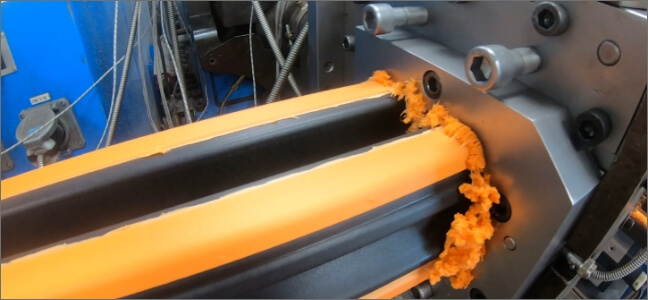

Single and Co-Extrusion

We’re experts in both single and co-extrusion. We’ll help you choose the best technique for your specific application. While single extrusion is great for simple profiles, co-extrusion is ideal for complex profiles requiring multiple materials or functional layers.

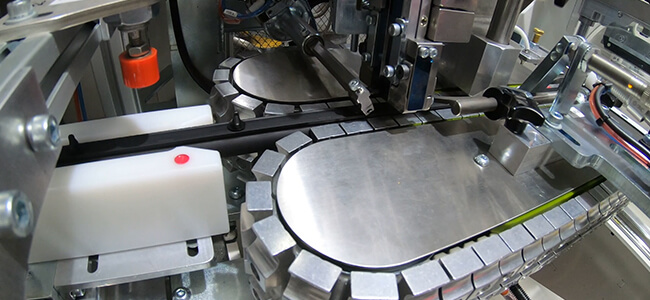

Secondary Operations

Moving components from one location to another can be an expensive part of plastic extrusion manufacturing. By performing secondary operations like bending, welding, and assembly under one roof, we eliminate unnecessary shipping activities that drive up product costs and lead times.

ONE SOURCE FOR EVERY PHASE OF MANUFACTURING

Plastic extrusion manufacturing is far more involved than simply pushing plastic through a die. With in-house design, manufacturing, and secondary operations backed by decades of experience, we deliver a single-source solution for our customers.

case study

SALVAGING A PROGRAM ON A TIGHT TIMELINE

A mistake in material selection can have devastating consequences in terms of process-ability, performance, cost, and delivery time. When that happened to a Tier 1 OEM supplier, we stepped in to help. In just 5 days, the customer had a functional part and met their delivery schedule.

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

PLASTIC EXTRUSION DESIGN GUIDE

Is your extrusion design optimized to meet the constraints of the extrusion process? This free guide offers a solid foundation in the requirements for successful extrusion design. Created by engineers for engineers, and based on decades of extrusion development and manufacturing experience.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields