Regency

INDUSTRY-LEADING TECHNICAL BLOW MOLDING EXPERTISE

Move beyond the uncertainties of shoot-and-ship suppliers. We specialize in producing highly engineered, custom blow molded products that help you drive cost out with dramatically reduced lead times.

END TO END BLOW MOLDING PROFICIENCY

Experience our full-service technical blow molding from design to prototype to production. We optimize design to produce parts that are easier to manufacture and assemble at the lowest cost.

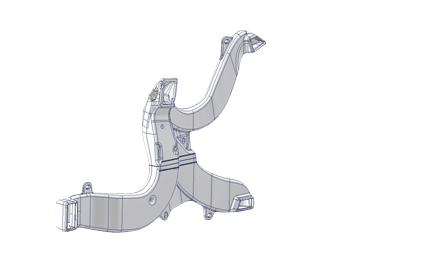

DESIGN & ENGINEERING EXPERTISE

Our design and engineering process produces optimized products and helps avoid defects. Our design expertise creates products that are uniform, repeatable, and able to meet stringent functionality and performance requirements.

SIMULATION SOFTWARE

We bring science to part design with simulation software that eliminates guesswork. Digital process modeling enables trial and error discovery early in design and allows tools to be cut in fewer steps at lower costs.

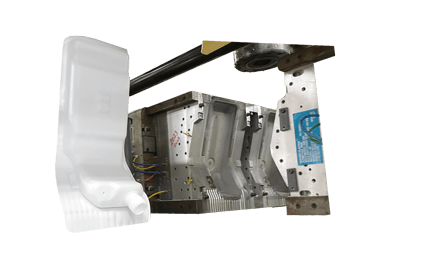

LARGE DUAL-HEAD PRESSES

Can your supplier handle large parts? With our massive 35lb dual-head presses, we can incorporates multiple variations between products in one molding cycle, resulting in shorter lead times and better consistency.EPA & CARB CERTIFIED

EPA and CARB regulations for molded fuel tanks in the US are some of the strictest in the world. We’re certified to supply tanks and diesel exhaust fluid (DEF) tanks that meet these tough requirements.

LEAK TESTING

Testing both before and during the molding process ensures all material specifications are met. As part of this process, in-depth leak testing is conducted to evaluate and guarantee complete structural integrity.

WELDING & ASSEMBLY

Does final part assembly add to your product costs? We perform a variety of secondary processes in-house such as welding a flexible cuff onto a rigid duct or insert molding sensor ports onto a reservoir, ensuring the best result for your application.

APPLICATIONS

We’re a trusted global supplier of technical blow molded products for automotive, lawn and garden, agriculture, and heavy equipment industries.

MANUFACTURING CAPABILITIES

We combine massive molding capabilities with in-house secondary processing to deliver technical blow molded parts as well as finished commercial products.

DESIGN & ENGINEERING

Our technical blow molding experts use the DFMA approach to optimize part design for the lowest cost while maintaining or exceeding performance requirements.

MATERIALS

We’re experts in a variety of materials for the technical blow molding process, and can assist with material selection to ensure optimal performance.

what our customers say about working with Us

Eric Plamper / Sr. Engineer: Fuel, Engine & Exhaust Systems / Stanley Black & Decker

Our Customers

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

BLOW MOLDING DESIGN GUIDE

Are you new to blow molding and don’t know where to start with your part design? Then our Blow Molding Design Guide is for you! Created by engineers, for engineers, this guide is the ultimate starting point to kick off a successful product design for the blow molding process.

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields