Rotational molding offers a number of benefits, but it’s not the best production process for every part. So how do you decide if it’s a fit for you? Understanding the advantages and disadvantages of the process is the first step towards making a decision with confidence.

ROTATIONAL MOLDING USES

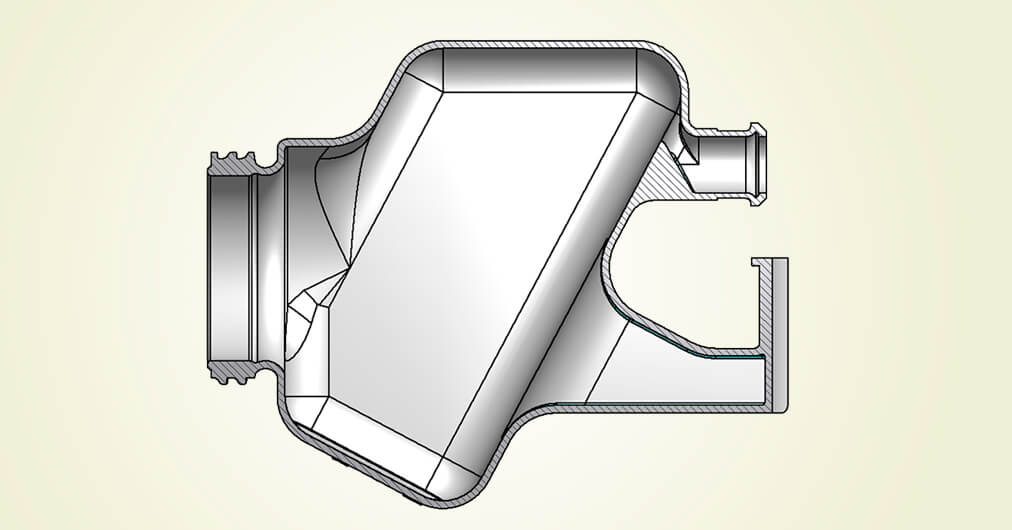

Rotational molding, also known as rotomolding, is a thermoplastic molding process best suited for large, one-piece hollow parts and double-walled open containers such as tanks, kayaks, and coolers. It’s most cost-effective for production volumes of less than 3,000 annually, making it ideal for inventors, start-ups, and small businesses.

Rotomolding is often used for parts that require high-quality finishes, uniform wall thicknesses, and high stability. Features such as inserts and spin weld attachments can be incorporated directly into the rotomold and foaming can be used to create thermal insulation and stiffness. Unlike competitive processes such as blow molding and thermoforming, rotomolding produces no pinch-off seams or weld lines, resulting in a finished product without the use of secondary processes.

ROTATIONAL MOLDING PROCESS

The rotational molding process is quite simple:

- A hollow mold is filled with powdered plastic resin.

- The mold begins rotating bi-axially and is transferred into an oven.

- The mold continues to rotate as the resin melts and coats the walls of the mold.

- The mold is cooled until the resin hardens into the desired shape.

- The rotation is stopped, and the mold is opened to remove the finished part.

Given the low-pressure, high-heat nature of the process, rotomold tooling is usually made from a soft metal such as aluminum and the majority of the resin used is polyethylene due to its low chemical degradation when exposed to high heat. Inserts, ribs, kiss-offs, undercuts, and foam reinforcements are often incorporated into the part in-mold or by means of secondary processing.

ADVANTAGES AND DISADVANTAGES OF ROTATIONAL MOLDING

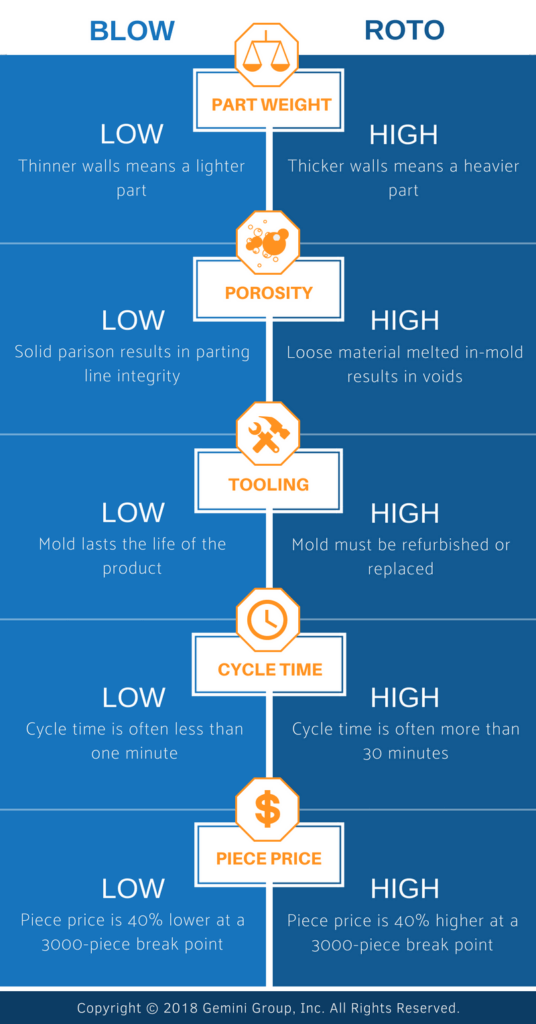

The main difference between rotational molding and competitive molding methods such as blow molding and thermoforming is that the resin melts into the mold walls instead of being forced by pressure. This distinction gives way to a number of advantages over other manufacturing processes, but also carries its share of drawbacks.

ADVANTAGES OF ROTATIONAL MOLDING

Rotomolding boasts a number of advantages over comparable molding methods:

- Low-cost tooling: low operating pressures allow rotomold tooling to be crafted from low-cost metals such as aluminum

- Consistent wall thickness: the constant rotation of the mold coats the walls evenly during both the heating and cooling processes

- Double-wall construction: complex double-walled open containers can be produced without secondary processing

- High stability: the molding material isn’t exposed to external pressure, increasing its stability and reducing the risk of defects in the finished part

- High strength: rotomolding creates thicker corners, reducing the risk of failure in these stress-concentration points

- Appearance: the soft metal used for the rotomold tooling easily accommodates surface finishes such as fine-detail textures, logos, symbols, and lettering

DISADVANTAGES OF ROTATIONAL MOLDING

As with any plastic molding process, rotomolding has its disadvantages:

- High cycle times: at eight rotations per minute, rotomolding can take up to three hours to complete one part

- Limited material options: raw material used in rotomolding must be readily converted from granules to a fine powder and must have high thermal stability, limiting material selection to poly-based resins

- High cost of raw material: material costs are high due to high thermal stability requirements, the cost of required additives, and the cost of grinding the material into a powder

- Low repeatability: the soft metal used in rotomold tooling must be refurbished or replaced after 3,000 cycles, inducing quality issues due to a lack of repeatability

- High labor costs: mechanization and automation have not yet been realized for rotomolding, requiring greater labor intensity than comparable manufacturing processes

Is Rotomolding Right for You?

The best way to decide whether or not rotational molding will work for your project is to look at your annual production volume.

If you need under 3,000 parts, rotomolding can suite your needs. However, due to its capacity limitations and the cost of refurbishing and rebuilding the tooling, it becomes cost-restrictive once you breach that threshold.

Bottom line: if you require an economy of scale, look into blow molding. It offers a number of advantages over rotomolding for high-volume production.

Customer Success Story

Just recently, a Tier 1 supplier to a major automotive OEM saw a 37% reduction in piece price when they converted their rotomolded DEF tank to blow molding:

| Cost Drivers | Roto Molding | Blow Molding |

|---|---|---|

| Tooling | $150,000 / yr | $200,000 / lifetime |

| Production Rate | 2 parts / hr | 70 parts / hr |

| Piece Price | $35 | $22 |

INTRO TO BLOW MOLDING DESIGN

If you’re new to blow molding and don’t know where to start, then our free Blow Mold Design Guide is for you! It will provide you with basic design guidelines for the injection, stretch, and extrusion blow molding methods so you can determine if this process is right for you.

Learn more

Blow molding reigns when it comes to part weight, porosity, tooling costs, cycle times, and piece price for high-volume production. If you’d like to learn more, check out our Extrusion Blow Molding Process page.

Our plastic molding experts are standing by to answer your questions. To contact us, please call our sales engineering team at 248-435-7271 or email us at plasticsales@geminigroup.net.