TPI

TWO-SHOT INJECTION MOLDING SOLUTIONS

When tolerances and on-time-delivery are important, OEMs choose us for two-shot injection molded parts.

Your Guide to Two-Shot

If you’re new to two-shot plastic injection molding, you might think it is more complex, more expensive, or more time consuming than other plastic molding processes. Taken alone, those may be true, but two-shot also creates considerable functionality and cost savings.

Maybe you’ve been turned off by a manufacturer’s quality or delivery issues? We’re here to tell you that you deserve better!

Whether you’re new to two-shot or needing a new two-shot supplier, we are here to help.

Success Story

When a major automotive OEM failed a side impact crash test, they relied on their Tier 1 supplier and us to develop a two-shot injection molding solution to reinforce the vehicle’s frame.

When tolerances and on-time-delivery are important, OEMs choose us for two-shot injection molded parts. We’re more than a manufacturer. We’re problem-solvers, working both with customers and vendors to build functionality, safety, and efficiency into everything we produce.

You can rest assured you’re getting the quality you need at a competitive market price when you choose us for your two-shot molding solutions.

Two-Shot Molding Process

STEP 1: Press closed; first shot injected into first mold

STEP 2: Press opened; part created from first shot is robotically transferred to second mold

There are two phases of the two-shot molding process.

The first is similar to traditional injection molding: A shot of resin is injected into a mold and cooled to form a solid part. In the second phase, the just-molded part is transferred to a second mold via a rotating platen or a robotic arm, and receives the second shot of resin – in, through or around certain parts of the first molded part, depending on the design. The two plastic resins then form a molecular bond and the multi-resin molded part is cooled and ejected.

The process isn’t difficult to understand, but it’s highly difficult to master.

It requires high levels of technical expertise and attention to detail, and even the smallest mistakes can cost big money, especially in high-volume production scenarios. That’s why it’s critical to find a highly capable supplier. Look for excellent supplier quality scorecards, defined processes to mitigate against flash, flow lines, and short-shots, and contingency plans to expand capacity as your business and your two-shot molding needs grow. Once you find a supplier, involve them early on in the design phase of your part. They can identify potential problem areas and engineer value into your product.

Two-Shot Injection Molding Applications

Two-shot injection molding is the ideal plastic molding process for complex, multi-color, and multi-material plastic products, especially in high-volume production scenarios.

From consumer goods to construction, two-shot molded components are used in nearly every industry, but are most commonly found in applications requiring high functionality.

- Movable segments or components

- Rigid substrates with soft grips

- Vibration or acoustic dampening

- Multi-color or multi-material components

TWO-SHOT INJECTION MOLDING DESIGN GUIDE

To get a jump-start on your two-shot part design, download our free Two-Shot Injection Molding Design Guide today!

Benefits of Two-Shot Molding

Compared to other methods of plastic molding, two-shot is ultimately a more cost-efficient way of producing an assembly with multiple components. Here’s why:

Part Consolidation

Two-shot injection molding reduces the number of components in a finished assembly, eliminating an average of $40K in development, engineering, and validation costs associated with each additional part number.

Improved Efficiency

Two-shot molding allows multiple components to be molded with a single tool, reducing the amount of labor needed to run your parts and eliminating the need to weld or join components after the molding process.

Improved Quality

Two-shot is carried out within a single tool, allowing for lower tolerances than other molding processes, a high level of accuracy and repeat-ability, and reduced scrap rates.

Complex Moldings

Two-shot injection molding allows for the creation of complex mold designs that incorporate multiple materials for functionality that cannot be achieved through other molding processes.

Two-Shot Molding Case Study

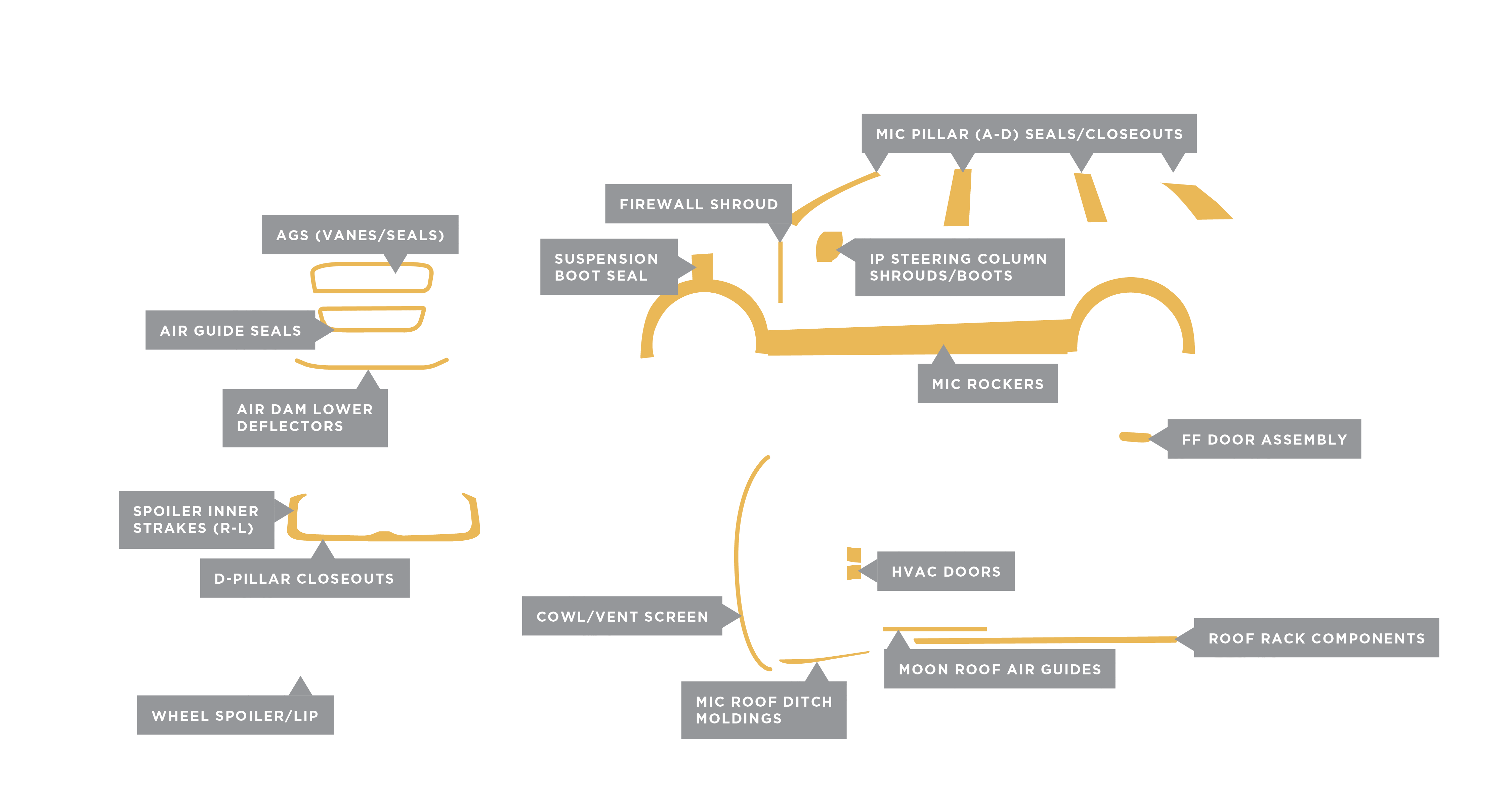

Active Grill Shutter Guides (AGS)

The customer is a Tier 1 international automotive supplier with an emphasis on innovation and technology. The company’s products include automotive exteriors, closures, roof systems, and seating – to name a few.

Two-Shot Terminology

- Boss: A raised cavity on the part designed facilitate alignment during assembly or attachment to other parts

- Cold-runner mold: A mold in which the runners are kept at the same temperature as the mold and must be ejected at the end of each molding cycle

- Draft: A slight taper built into the mold walls to facilitate removal of the part from the mold

- Flash: Material that forms in the seams or parting lines of the mold cavity

- Gate: The channel through which molten plastic resin enters the mold cavity

- Runner: A channel within the mold through which molten resin flows from the machine sprue to the cavity gate

- Short shot: Failure to fill the mold completely with resin, resulting in missing geometry and melted edges

- Shrinkage: The contraction of a plastic molded part as it cools

- Shut-off: An area where the mold seals against the other half of the mold, an insert, or the first-shot substrate formed in the two-shot molding process, to form a slot, hole, or void

- Hot-runner mold: A mold in which the runners are insulated or heated to keep resin in a molten state to facilitate flow control

- Knockout pin: A pin that ejects the molded part from the mold

- Living hinge: A thin section of the part along which the part can fold

- Parting line: A mark on a molded part indicating where the two halves of the mold meet in closing

- Rib: A thin wall-like feature that increases the bending stiffness of wall sections and bosses

- Sink mark: A surface indentation caused by differential rates of cooling in areas with significant changes in wall thickness

- Sprue: The channel through which molten plastic resin flows from the machine nozzle to the mold runner

- Undercut: A protrusion, hole, cavity, or recessed area in the part that impedes ejection from the mold, therefore requiring movable mechanisms within the mold to form the shape

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields