TPI

Two-Shot Design & Engineering

From conception to production, our engineering team has your back. By leveraging our expertise and industry knowledge, we provide our clients with the guidance and support needed to achieve optimal designs and successful outcomes in two-shot injection molding projects.

Design & Engineering Expertise

We aim to optimize the two-shot injection molding process for our clients. We understand the importance of considering factors such as material compatibility, part geometry, and production efficiency.

With our on-site design support, we collaborate closely with our clients to understand their specific requirements and translate them into innovative and functional designs. Our team of experienced designers and engineers leverage the latest CAD software and techniques to create precise and optimized designs for two-shot injection molding.

We also offer product development services, assisting clients from the conceptual stage to final production. Through rapid prototyping and trial runs, we ensure that the design meets the desired specifications and functionality before proceeding to full-scale production. This iterative process allows for quick adjustments and improvements, saving both time and cost.

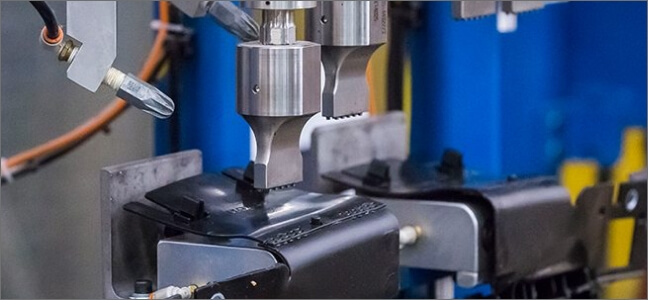

In-House Tooling

Our in-house tooling department is equipped to create both prototype and production molds, as well as deflash, trim, EOAT, fabrication, assembly, and test fixture tooling. By having these capabilities in-house, we maintain greater control over the entire manufacturing process, ensuring high-quality tooling and faster turnaround times.

Secondary Operations

Secondary operations are crucial for enhancing the functionality and appearance of the final products. From welding to riveting and staking to full assembly, we provide customers with a one-stop solution for all their two-shot injection molding needs, resulting in high-quality, finished products that meet their exact specifications.

case study

Salvaging a Two-Shot Seal

The customer was having issues sealing off an active grille shutter (AGS) system with the air guide seals. Designed to help OEMs meet CAFE standards by redirecting air around the vehicle to reduce drag, the sealing components of the system are absolutely critical.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Two-Shot Molding Design Guide

Two-shot design can deliver a competitive advantage far above other molding processes, especially for complex parts. Learn the benefits of the process and explore the special design requirements needed to make it work in this free guide created by engineers, for engineers.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields