TPI

TWO-SHOT INJECTION MOLDING APPLICATIONS

Two-Shot injection molding is the ideal molding method for applications that require two or more materials, such as flexible seals with rigid bases, plastic grips and handles, and parts with structural reinforcements.

Two-Shot Injection Molding

Using two-shot injection molding, we can produce two-component or two-color plastic injection molded parts in one machining cycle, reducing overall cycle time and eliminating additional assembly costs. Two-shot is the ideal process for high-volume production of products with the following attributes:

- Rigid and flexible components

- Multiple colors and surface grades

- Vibration and noise dampening characteristics

- Sealing functionality

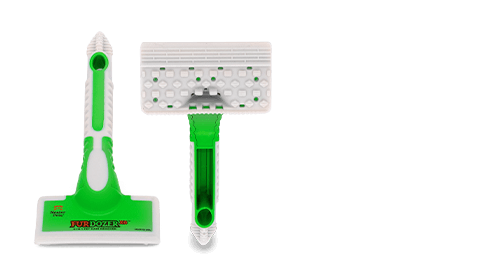

Insert/Over Molding

Using insert molding and over molding, we can mold plastic directly on to metal components and assemblies, eliminating the need for messy adhesives and fasteners. Insert/over molding is the ideal process for the high-volume production of products with the following features:

- Plastic grips and handles

- Metal fasteners

- Magnets

- Structural reinforcements

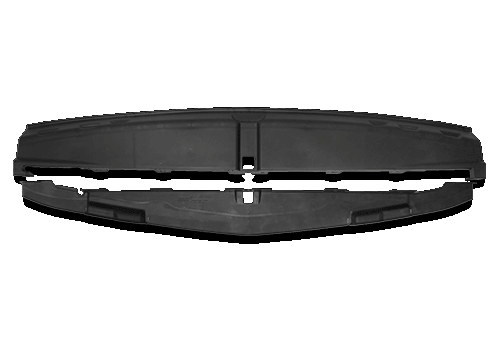

Automotive

- Structural (SORB rocker, pillars)

- Sealing (baffles, carriers)

- Active grill shutter (seals, rods)

- Interior (panels, trim)

- Exterior (mud guards, spoilers)

- Bellows and cuffs

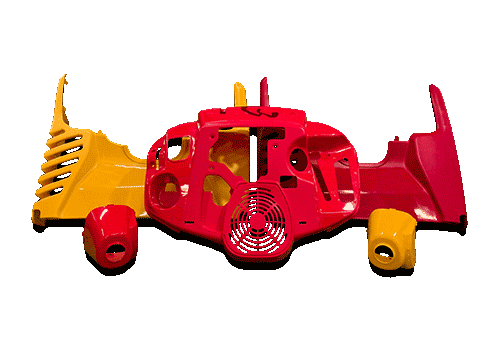

Lawn & Garden

- Grips and handles

- Housings (motor, battery)

- Guards (toe guards, stone flaps)

- Covers (deck skids, wheels)

- Vibration and noise dampening parts

- Dual-durometer seals

Other

- Consumer products

- Power tool components

Engineering Success

Got an idea for a part requiring the innovation of two-shot? Not sure where to start? We have the design and manufacturing experience to help solve your company’s product dilemma and give you a competitive advantage.

We believe in proactive communication and collaboration early on in the design and engineering phase. This allows us to incorporate DFM right from the start, eliminating potential problems before they add to your cost and development time.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Two-Shot Molding Design Guide

Two-shot design can deliver a competitive advantage far above other molding processes, especially for complex parts. Learn the benefits of the process and explore the special design requirements needed to make it work in this free guide created by engineers, for engineers.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields