GPI, GT Plastics, Sierra, GPM

SECONDARY PROCESSES FOR PROFILE EXTRUSION & CO-EXTRUSION

Our profile extrusion capabilities go beyond the initial extrusion process. We offer a range of secondary processes specifically tailored for profile extrusion to further enhance the functionality and aesthetics of your products.

In addition to the plastics extrusion process, we offer a variety of in-house secondary operations for your extruded products enabling parts to remain in one location from inception to completion, thereby reducing time to market and eliminating unnecessary shipping costs.

PAD PRINTING

With our advanced pad printing techniques, we can apply high-quality graphics, logos, or product information directly onto the extruded profiles. This allows for enhanced branding and visual appeal.

INTEGRATION OF PUSH PINS

We have expertise in integrating push pins into the extruded profiles, providing convenient fastening solutions for various applications. Our precise integration ensures secure and reliable connections.

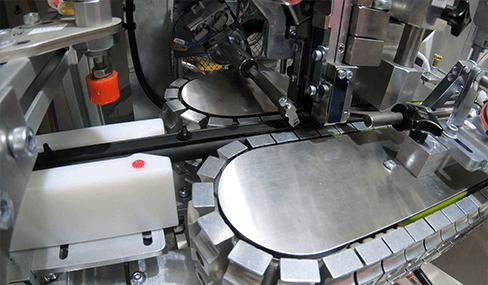

CNC ROUTING

Utilizing our state-of-the-art CNC routers, we can achieve intricate and precise cuts, shapes, and designs on the extruded profiles. This enables customization and ensures a perfect fit for your specific requirements.

THERMAL BENDING

Our thermal bending process allows us to create curved or angled sections within the extruded profiles. It combines the cost saving benefits of extrusion with the forming benefits of injection molding.

ULTRASONIC WELDING

Through ultrasonic welding, we can join different sections of the extruded profiles with a molecular bond. This technique can be used to join plastic to plastic, plastic to vinyl, and plastic to metal.

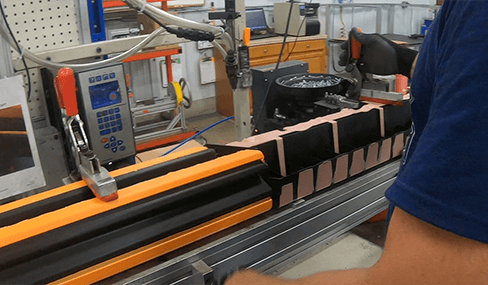

LAMINATION

Our lamination process involves applying a protective or decorative layer onto the extruded profiles. This enhances their appearance, provides additional protection, and allows for easy cleaning.

ASSEMBLY

We are not simply a plastics extruder. We will fully assemble your parts in-house so they are ready to install upon delivery, eliminating the need to ship them to a third party and saving you time and money.

WHY CHOOSE US?

We understand the importance of secondary processes in profile extrusion. With our expertise and advanced techniques, we can take your extruded profiles to the next level, delivering products that meet your exact specifications and exceed your expectations.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields