Valley Enterprises, GGIT

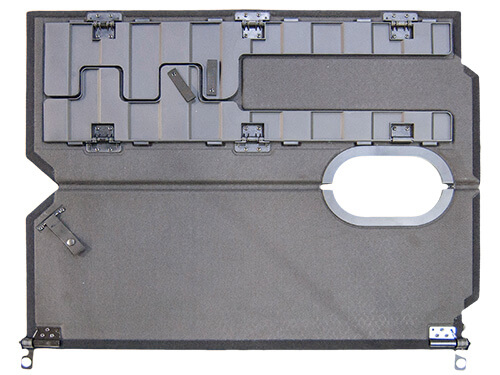

Setting the Standard in Load Floor Excellence

We stand out as an industry leader in load floor design and manufacturing. Our team ensures structural integrity, weight optimization, and aesthetics without compromise. With cutting-edge technology, we create load floors that enhance safety, functionality, and user experience.

Features

Our dedication to innovative engineering and high-quality manufacturing enables us to integrate a range of cost-effective features:

Composite Spray Molding (Baypreg®)

Our advanced composite spray molding technology ensures exceptional load floors with superior strength and durability.

Reversible, Washable, and Brandable

Experience the convenience of a reversible, washable surface that can also be customized with your branding, while elevating your consumer’s experience.

Industry-Leading Edge-Wrapping

We’re proud of our attention to detail and quality, ensuring your product not only looks great but also stands the test of time.

Hinges Made to Last

Our load floors incorporate the latest in hinge technology, including living hinges and friction stay-open hinges, enhancing functionality without adding unnecessary expense.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields