Valley Enterprises, GGIT

Bespoke Automotive Interior Trim Applications

We specialize in custom processes for automotive interior trim components, including cargo management, load floors, and seatbacks. Our team crafts unique solutions to boost quality, cut costs, and speed up your time-to-market.

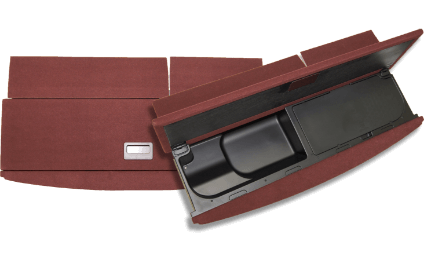

CARGO MANAGEMENT

Our expertise in designing and manufacturing cargo management systems begins with a deep understanding of consumer preferences and market trends.

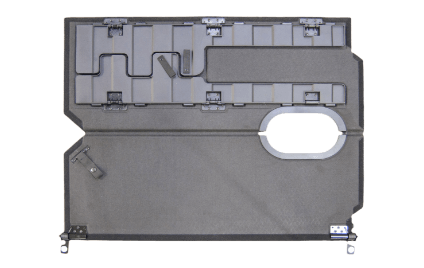

Automotive Load Floors

We utilize cutting-edge technologies, including Baypreg®, composite spray molding, and compression molding, to produce load floors that are lightweight, durable, and built to last.

Seatbacks and Other Interior Trim Applications

Our versatile seatback and interior trim solutions cater to automotive needs, backed by our expertise and extensive product lineup for seamless interiors.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields