Valley Enterprises, GGIT

AUTOMOTIVE INTERIOR TRIM PRODUCTS FOR OEMs & TIER-1 SUPPLIERS

Nearly every major automotive OEM partners with us to design and manufacture their cargo management systems, load floors, and other interior trim components. Our early access to trends and customer preferences enables us to provide innovative solutions to meet the evolving needs of the market.

AUTOMOTIVE INTERIOR TRIM COMPONENTS WITH ADDED VALUE

Discover why we are the number one supplier of cargo management systems in North America.

MARKET LEADERSHIP

We are the leading supplier of cargo management systems in North America. Partnering with nearly every major OEM gives us unparalleled access to emerging trends and technologies, enabling us to offer the most advanced features and functionalities.

INNOVATION

Heavy investment in automotive interior trim R&D enables us to bring new ideas to market. Our patented 3D Composite Spray Molding process and U-SKIN surface technology demonstrate our leadership in innovation.

IN-LINE VEHICLE SEQUENCING (ILVS)

We recognize that assembly errors and inventory control are a constant challenge for automotive OEMs. Our ILVS capability helps solve these challenges by delivering parts just-in-time and in the exact order they will be used on the assembly line.

DESIGN RESPONSIBLE

We go far beyond simply producing parts to print. With decades of design and manufacturing experience, we can confidently accept full design and validation responsibility or work as a design partner.

VALUE ENGINEERING

Opportunities for controlling costs exist in every phase of bringing a product to market. We have years of experience in applying value engineering principles to part design, material selection, and process choice to drive cost out of your product.

RAPID PROTOTYPING

Rapid prototyping gives the ability to quickly evaluate and refine your ideas before they go into production. Our fast and full-spectrum prototyping capabilities reduce risk and enable shorter time to market.

APPLICATIONS

We partner with OEMs and suppliers across the globe to develop innovative solutions for automotive interior trim applications and can quickly pivot to changing requirements. From cargo management systems to load floors to seatbacks, we can deliver.

MANUFACTURING CAPABILITIES

With a variety of production processes available, we excel at driving cost out of your product and decreasing time to market. Our expert team thoroughly examines each project and recommends the process that will produce the best outcome.

DESIGN & ENGINEERING

With decades of design and engineering experience, our team works alongside yours to identify ways to improve product performance and cost. We’re experts in value-added engineering and manufacturing and offer full design responsibility.

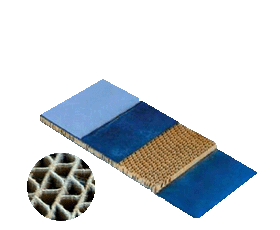

Materials

We offer a wide range of materials for automotive interior trim applications. From composite spray molding (Baypreg) to specialty plastic composites, our unmatched flexibility in material and processing ensures optimal performance of every part.

Our Customers

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields