Regency

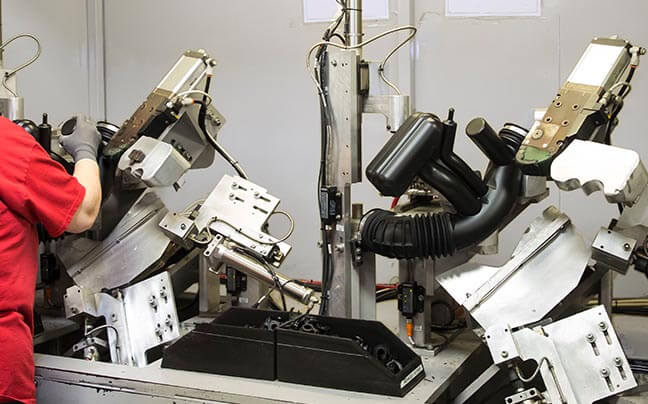

ENHANCE FUNCTIONALITY WITH SECONDARY OPERATIONS

Whether your blow molded part is large or small, simple or complex; we specialize in a variety of techniques to add features and functionality to your part in-house, eliminating the need for third-party processing.

WELDING

We offer both infrared and friction welding techniques to weld plastic to plastic, plastic to vinyl, and plastic to metal. Each technique has it’s own benefits:

Infrared welding

- Suitable for high-volume parts

- Provides superior weld integrity

- Achieves consistent results

Friction welding

- Ideal for low-volume parts

- Offers flexibility and versatility

- Minimal tooling requirements

ADDITIONAL SECONDARY OPERATIONS

Trimming

We utilize advanced automated trimming processes to enhance the dimensions and functionality to your part. This encompasses various operations such as:

- Creating cutouts

- Drilling holes

- Punching tabs

Assembly

We create multi-component assemblies in-house, which are ready for installation upon delivery. Some of the assembly operations we offer include:

- Automated integration of ROV and level sensors

- Foam and acoustic pad assembly

- Riveting and staking

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields