Regency

REDUCE FIELD-FAILURE WITH IN-PROCESS TESTING

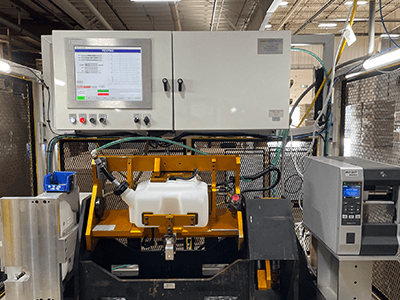

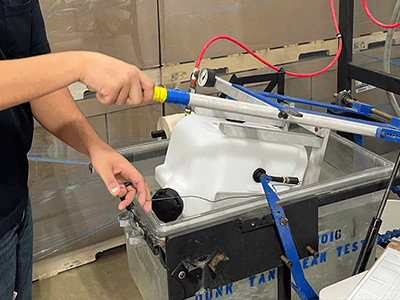

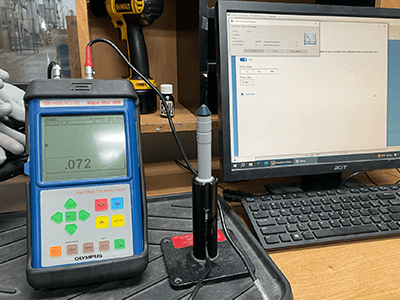

When it comes to ensuring the quality and reliability of your blow molded parts, we take no chances. We perform a variety of testing before and after the blow molding process to ensure your part requirements are met and reduce your risk of field-failure.

IN-PROCESS TESTING METHODS

To make sure that your blow molded part meets all of your specifications such as material properties, tensile strength, load, thickness, and more, we perform thorough testing both on the production floor and in our dedicated testing lab. We tailor our testing procedures to match the design and requirements of your specific part.

We employ the following techniques to guarantee the quality of your parts:

- Rollover Valve (ROV) Testing

- Mass Flow Testing

- Submersion Testing

- Pressure Decay Testing

- Weld Strength Testing

- Tensile Testing

- Material Thickness Analysis

- Destruction Testing

- Color/Gloss Testing with Spectrometers

With our comprehensive in-process testing methods, we ensure that every aspect of your blow molded product is thoroughly evaluated and meets the highest quality standards. By minimizing the chances of field-failure through rigorous testing, we enhance the reliability and performance of your parts. Trust our expertise and dedication to exceed your expectations.

Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

BLOW MOLDING DESIGN GUIDE

Are you new to blow molding and don’t know where to start with your part design? Then our Blow Molding Design Guide is for you! Created by engineers, for engineers, this guide is the ultimate starting point to kick off a successful product design for the blow molding process.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields