GPI, Sierra, GT Plastics, GPM

GET YOUR FREE COPY TODAY!

"*" indicates required fields

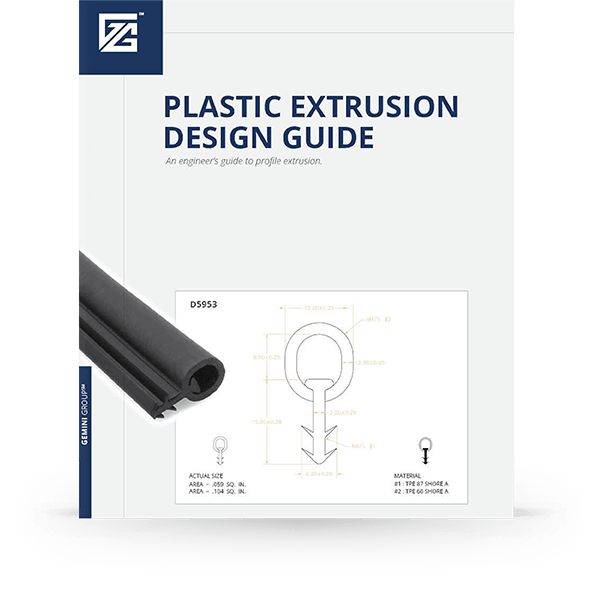

Plastic extrusion design

For engineers, by engineers.

With over 7,000 extrusion dies under our belt, we know a thing or two about plastic profile design. So we wrote a guide to share our insights! Simply fill out the form below and we’ll send you our Plastic Extrusion Design Guide right away.

Optimize Design and Drive Cost Out!

You’re going to waste thousands on tooling and prototyping if your plastic profile design isn’t optimized for the extrusion process. This guide will help you avoid the chronic and tell-tale design issues that plastic extrusion suppliers wish you knew about.

You’ll learn everything you need to take your extruded plastic part design to the next level:

- Plastic Profile Extrusion Process

- Advantages/Disadvantages of Profile Extrusion

- Applications For Plastic Extrusions

- Cost Drivers of Custom Plastic Extrusions

- Tolerances For Extruded Plastic Parts

- Plastic Extrusion Design Guidelines

This design guide is not exhaustive; the amount of information available is simply too great. However, it serves as a starting point to better understand the capabilities and limitations of designing extrusions.

An Insider's guide

We’ve spent decades developing over 7,000 plastic extrusion profiles and manufacturing millions of dual- and tri- durometer plastic extrusions. We’ve helped thousands of engineers just like you with material selection and profile extrusion design.

Our team is proud to present to you the culmination of over 45 years of experience in extrusion design and manufacturing; truly, the next best thing to working directly with our team.

So, what are you waiting for? Dive in!

You want to design your seal right the first time. Minimal changes, minimal headache. We’re right there with you. With over 7,000 extrusion profiles under our belt, we know a thing or two about extruded seal design. So we wrote this guide to give you a better understanding of what to consider in every step of the DFM and DFA process and answers questions like;

- What does every good seal design have in common?

- What are the constraints of the extrusion process?

- What tolerances can be expected?

- What are the cost-drivers?