GPMI, CT

FORGE TOOLING SPECIALISTS, AT YOUR SERVICE

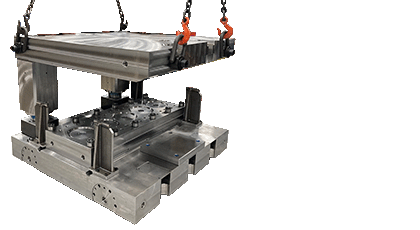

forge tooling Products

Equipment & Capabilities

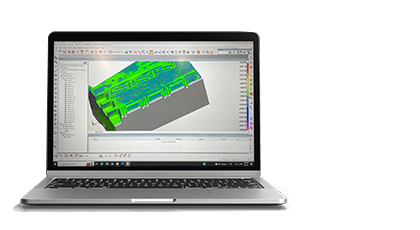

DESIGN & ENGINEERING

Our forge tooling specialists are true masters in their craft with a combined 168 years of experience, allowing us to routinely recommend material, design, and process modifications that extend tool and die life, enhance performance, and improve operational efficiency.

what our customers say about working with Us

“They could be considered an extension of our forging department here at the plant. Through thoughtful inventory practices, quality work, and quick turnaround, they’ve been an integral part of our forge tooling success. Their stocking agreement with min/max quantities of consumable tooling has been very beneficial. Any issues that do arise are handled with a phone call and quick correction. Our forging plant looks forward to continuing our relationship with this team.”

Adam Stricker / Forge Engineer / Hendrickson

FORGE TOOLING SPECIALISTS BORN OF BOOTS-ON-THE-GROUND EXPERIENCE

We’re not just another machine shop. We’ve spent decades walking the floors of our customers’ forging operations, helping solve their toughest forging challenges and uncovering opportunities to improve efficiency. Our customers see us as an extension of their own team, committed to the success of their company as a whole.

EXPERTISE

We live and breathe forge tooling. We have a deep understanding of the industry, the forging processes, and the challenges our customers face daily, which is why we’re often called in to help when things aren’t going as planned. We don’t just make tooling, we drive forging operations forward through innovation and problem-solving. Our proven track record can’t be beat.

CAPABILITIES

Everything under our roof is dedicated to forge tooling, including over 100 CNC machines and over 100 highly skilled specialists. Whether you need a 16,000lb bolster or a 40lb punch we’re the ultimate source for all of your tooling design, build, and refurbishment needs for forging hammers, presses, ring rolling, upsetters, coining, and trim tooling.PARTNERSHIP

We’re not your typical build-to-print supplier. We routinely provide on-site consultations partnering with customers to solve problems, identify opportunities for improvement, and offer expert guidance to optimize performance and efficiency.SURFACE TREATMENT

Your choice of material, surface finish, and hardening techniques is critical to the life of your tool. We can help with that. We offer a variety of options to improve performance, including in-house heat treat, cryogenic treatment, black oxide treatment, and ion-nitriding.STOCKING PROGRAM

Our stocking programs for high-usage tools offer the benefits of reduced lead times, lower inventory costs, and volume-based pricing. Our customers have realized savings of 25-40% on a per-tool basis, as well as delivery times of only 2-5 days.

CAPITAL INVESTMENT

Our financial stability as a large and diversified organization allows us to strategically invest in new equipment and technologies for our forge tooling team. We’re constantly expanding our capacity and capability to meet evolving needs of our growing customer base.

Our Customers

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

REDUCING THE COST OF YOUR FORGING PROCESS

We’ve spent decades helping forgers across the country enhance tool performance and improve operational efficiency, and we want to help you, too. Learn how to eliminate wasted time, money and other precious resources in our free e-book written by experts, for experts.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields