TTE, MSCED, TRD

Crafting Excellence through Advanced Engineering

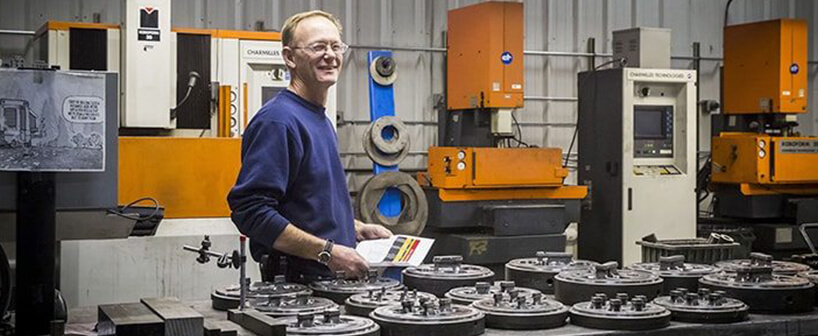

A Wealth of Die Design Knowledge

We possess an impressive bank of die design knowledge, obtained over years of experience. Our design file base boasts over 500,000 successful dies, a testament to our commitment to crafting top-notch tooling solutions.Streamlined Communication

Our commitment to customer satisfaction extends to our communication processes. We maintain an Intranet Customer Specification bulletin board, ensuring a seamless exchange of critical information.

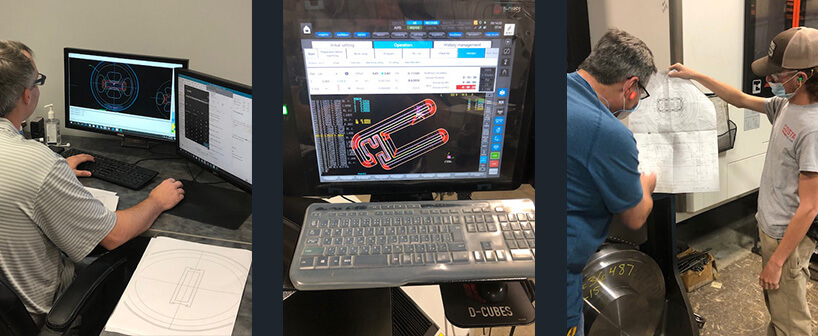

Tailored Machining Programs

Customization is at the heart of what we do. Our in-house software writers create specific machining programs, tailored to your unique needs, ensuring precision in every detail.

Seamless Integration of Technology

Our CAD/CAM computer systems are expertly networked with our CNC machines, guaranteeing a seamless flow of information. This integration results in precision and repeatability that’s second to none.

Unmatched Design Capacity

Our Engineering Department is a well-oiled machine, producing up to 500 designs a week, including press tooling. With a keen eye for detail, we bring your vision to life, meticulously checking geometry, dimensions, and tolerances as we receive them.

Success on the First Run

The collaborative efforts of our engineering and technical staff specialists result in dies that succeed on the first run more than 90% of the time. We pride ourselves on consistently delivering tooling solutions that exceed expectations.Wherever You’re Located, We’re Here to Help

18 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields