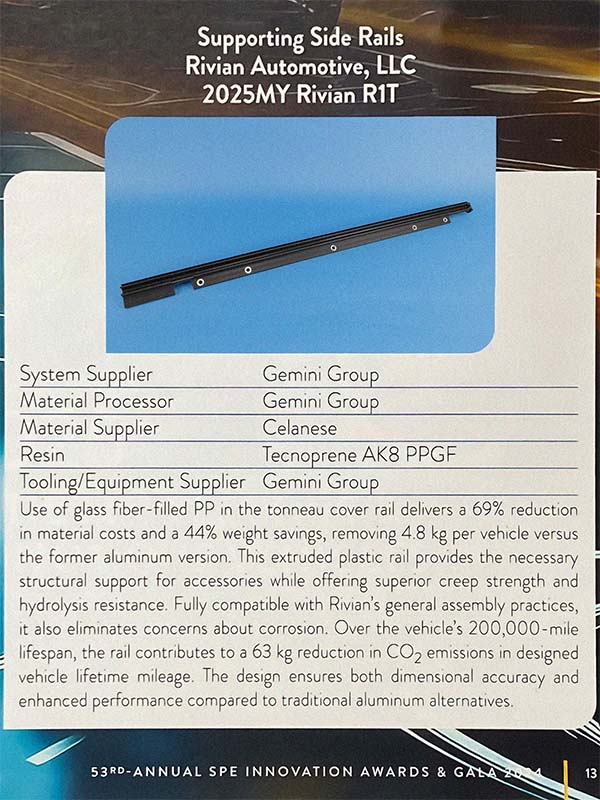

Gemini Group’s Role

Gemini Group’s plastic extrusion company partnered closely with Rivian to convert their initial rail design from aluminum to structural plastic. Our team also built all tooling in-house and developed all fabrication and assembly automation.

Challenges

Our journey wasn’t without its hurdles. From mastering a new material to rethinking assembly processes, our team adapted, innovated, and overcame.

Material

Converting an aluminum part to plastic is no cake walk, especially when working with a notoriously demanding plastic like glass fiber-filled polypropylene (PP). It required extensive trial and error to master the material for this unique application. Only after optimizing the pre-heating process, screw designs, and temperature profiles, we successfully managed to achieve consistent extrusion.

Complex Assembly Process

The initial design required 15 components to be assembled into the final part. Through the extensive collaboration between our engineering and production teams, we successfully redesigned the part and re-worked the manufacturing process to eliminate 5 components.

The Result

Our team delivered a solution that not only meets Rivian’s strict performance demands but also sets new standards for the cost and environmental impact of these types of parts.

Material

By replacing aluminum with glass fiber-filled PP, we reduced material costs by 69% and part weight by 44% – removing nearly 11lbs per vehicle.

Environmental

Over a 200,000-mile lifespan, this part contributes to a 139lb reduction in CO2 emissions.

Performance

Compared to aluminum, the structural plastic extrusion provides superior creep strength and hydrolysis resistance, while eliminating concerns about corrosion.Team Recognition

None of this would have been possible without the determination and collaboration of our incredibly skilled team. They all deserve recognition, however we’d like to take a moment to give a special shout-out to a few who played an instrumental role in the project:

- Eric Sweeney and the Production Trial Run (PTR) Team for their expertise in die design, and development of the extrusion tooling and extrusion process.

- Tim Sweeney and his team for their seamless integration of the router and automation assembly cell.

Celebrating the Journey

While we didn’t take home the award, being named a finalist in such a competitive category is a testament to our team’s hard work and ingenuity.

Collaborating with Rivian on this project was a highlight for us, allowing us to push the boundaries of what’s possible in material, design, and sustainability. Being part of a project that offers significant weight savings to the vehicle and cost savings for our customer is an absolute privilege.

A huge thank-you to Rivian for their partnership and to everyone who contributed to the innovation, and to SPE for recognizing our contributions.

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields