GPMI, CT

FORGING DIES,

QUICK-CHANGE TOOLING,

AND COMPLETE TOOLING SYSTEMS

Extend Die Life

Through careful consideration of tool steel, heat treatment, and surface treatments, we can help you experience a 2-3x improvement in die life.

Reduce Downtime

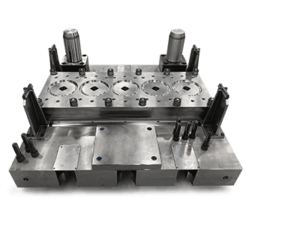

Our quick-change tooling systems and insert designs allow rapid change-over, eliminating the need to remove the entire die block assembly to change out a single die.

Reduce Tool Costs

With our stocking program for high-usage tools, our customers take advantage of lightning fast lead times and bulk pricing with the convenience of paying only when we ship.

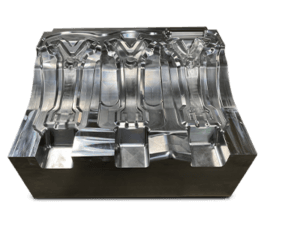

Full Forge Tooling Systems

Forge tooling is all we do. We understand the nuances of the forging process, and how every tool must work seamlessly together to maximize productivity. That’s why we take a holistic approach to tooling design, optimizing every part of the system for your unique operating parameters. Our technical experts are committed to making sure your machines run as efficiently as possible.

Quick-Change Tooling Systems

Dies, Punches & Mandrels

Bolsters & Cassettes

Our bolsters and cassettes are made for optimal strength, compatibility, and ease of maintenance ensuring precision and reliability of your forged parts.

Stocking Programs

Die Refurbishment

case study

SIMPLIFYING CHANGEOVER

Our engineers helped reduce downtime by 87% and tooling costs by 10% for a forger of heavy truck components, simply by redesigning the punch holder and punch.

Our Customers

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields