GPMI, CT

Massive Capabilities 100% Dedicated to Forge Tooling

LARGE FORMAT MACHINING

(3) Toshiba and Union Large Format Boring Mills

(1) Dual Column Bridge Mill

(1) Millutensil Spotting Press

Up to 158” x 118” x 180″ table size

50 Ton Capacity

Our large format milling machines and spotting press allow us to produce massive bolsters, cassettes, and other large format tooling.

PRECISION CNC MILLING

(43) Okuma, Makino, and Mazak CNC Milling Machines

5-Axis and high-speed milling capability

Up to 55” x 47” x 55” horizontal table size

Up to 24” x 55” x 78” vertical table size

We combine deep machining know-how and unique work-holding fixtures to run our highly efficient and precise milling operation.

PRECISION CNC TURNING

(40) Okuma and Mazak CNC Lathes

Up to 24” diameter, 60” long

(1) Toshiba Vertical Turn Lathe w/ Milling Capability

Up to 60" diameter, 53" long

Up to 6-jaw chucking capabilities

Live milling capabilities

Off-center radial and face cut features

These lathes are making chips on all shifts with full part inspection, minimizing programming time and maximizing production efficiency.

GRINDING AND HONING

(10) Okuma ID/OD Grinding and Sunnen Honing Machines

16” diameter, up to 40” long

(5) Okamoto Surface Grinders

20” x 40” table size

Our grind department is temperature and humidity controlled, allowing us to hold the tight tolerances your toughest project requires.

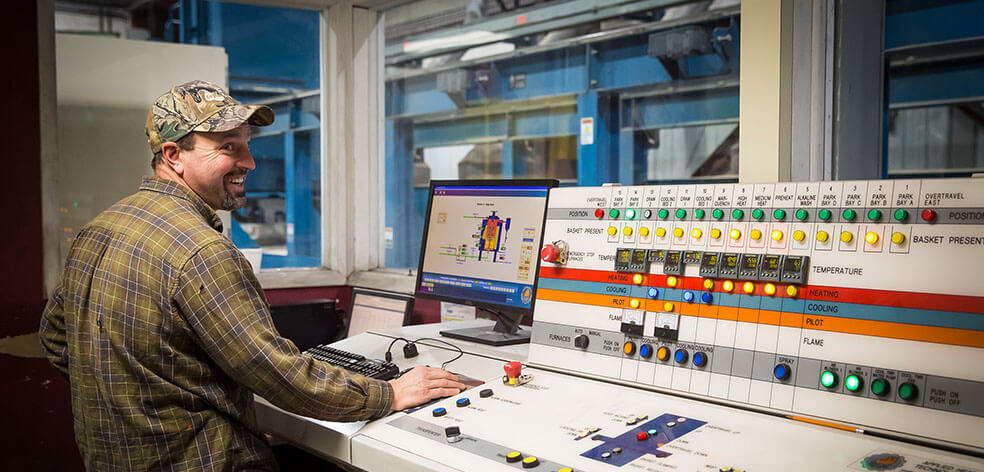

HEAT TREAT / BLACK OXIDE / CRYOGENICS

2,000 lb Carburizing Furnace

2 Bar Vacuum Furnace

Black Oxide Coating

Salt Pot

Fluidize Bed

Cryogenics

Compare our cryogenically and surface treated tools head-to-head against your existing tooling to see how much additional tool life you can achieve.

Our comprehensive surface treatment capabilities allow close monitoring of operations that are often outsourced by other suppliers, saving you time and money.

WIRE AND SINKER EDM

(5) Fanuc Wire EDM Machines

20” x 30” table size

(1) EDM Hole Burner

(2) Makino CNC Sinker EDM

98” x 55” x 32” table size

Our climate-controlled wire EDM department allows for small or odd-shaped angles and intricate contours.

Our EDM capabilities are especially valuable for cutting pre-hardened steel, as it eliminates the need for heat treatment to soften and re-harden the material. EDM can also be used on exotic metals such as titanium, hastelloy, kovar, and inconel.

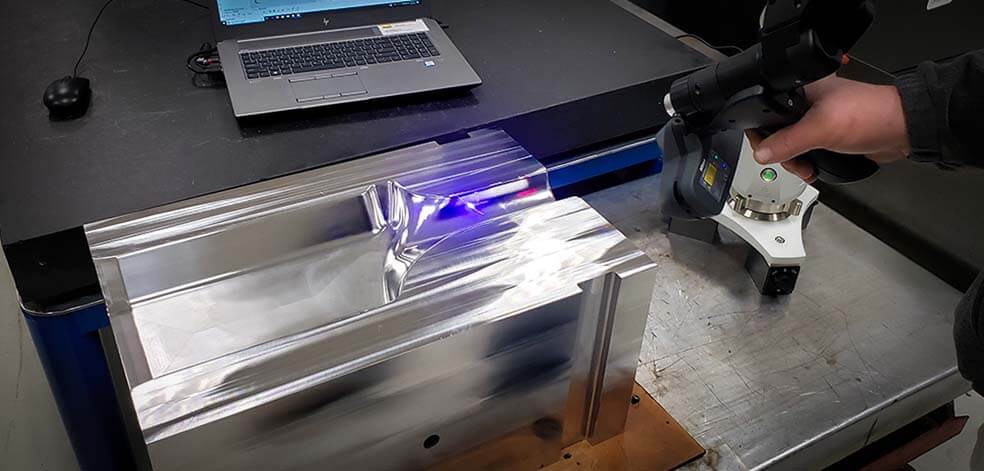

QUALITY AND ENGINEERING

Inspection

Part Marking

CAD/CAM

DEFORM Simulation

Our quality and engineering staff are armed with state-of-the-art equipment and receive ongoing training on critical inspection processes and capabilities.

Our facilities are armed with a full complement of quality and engineering equipment.

Inspection

Our inspection equipment includes two 3D laser scanners by Nikon and four CMMs by Zeiss, Wenzel, and Brown & Sharp, and is located in dedicated climate-controlled labs with some units strategically located so operators can conduct critical in-process inspections.

Part Marking

We employ laser etching, pin marking, and other techniques to customize your part with permanent text, graphics, barcodes, or logos.

CAD/CAM

Our CAD/CAM department is equipped with the latest technology from Mastercam, Work NC, Solidworks, ProE, Delcam, and NXUnigraphics.

Simulation

We perform full forge tooling design and simulation with DEFORM engineering software, enabling us to predict material flow, thermal behavior, and deformation with precision.

LOGISTICS

We maintain local logistics warehousing to accommodate incoming raw stock, as well as finished goods ready to ship.

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields