TPI

360-DEGREE TWO-SHOT INJECTION MOLDING

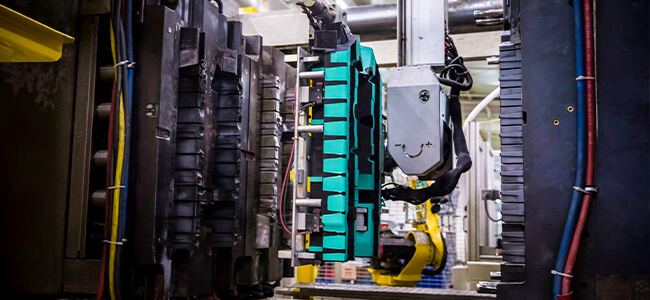

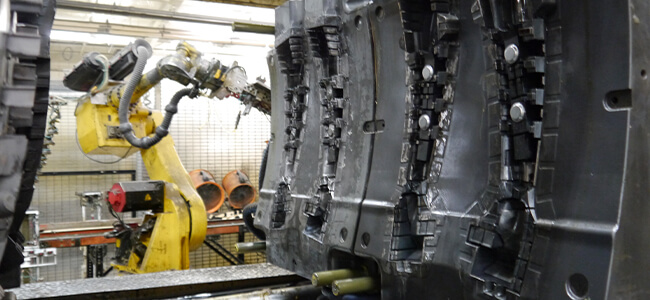

Our expertise in the two-shot injection molding process sets us apart. With advanced capabilities, streamlined processes, reduced production times, enhanced part designs, and the ability to create complex multi-material components with exceptional quality and reliability.

Two-shot & Multi-shot Molding

No job is too big or too small for us. Our (40)+ injection molding presses ranging in size from 85T to 1,630T, in conjunction with huge levels of automation, enable us to create complex products with a high level of accuracy and repeatability.

Insert & Over Molding

The insert and overmolding processes are used to mold 360 degrees around a first shot of plastic. It can be used to combine plastic or metal components in-mold which increases part consistency and reduces the need for post-mold operations.

Two-Shot Molding Case Study

Active Grill Shutter Guides (AGS)

The customer is a Tier 1 international automotive supplier with an emphasis on innovation and technology. The company’s products include automotive exteriors, closures, roof systems, and seating – to name a few.

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

TWO-SHOT INJECTION MOLDING DESIGN GUIDE

To get a jump-start on your two-shot part design, download our free Two-Shot Injection Molding Design Guide today!

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields