TPI

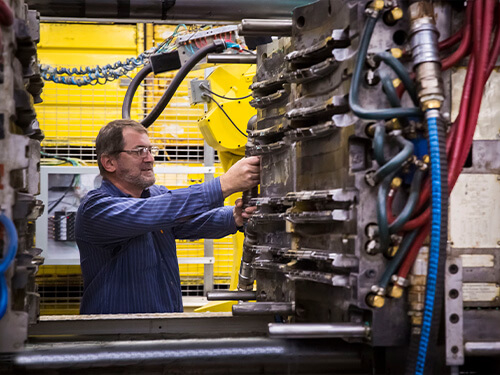

IN-HOUSE INJECTION MOLDING TOOLING DESIGN & BUILD

Our injection molding design capabilities allow us to provide rapid prototypes of your parts as well as eliminate wasted time and cost associated with shipping your mold to different facilities for tooling or engineering purposes. This means faster implementation of engineering changes and shorter time to market for your injection molded parts.

In-house Injection Molding Design

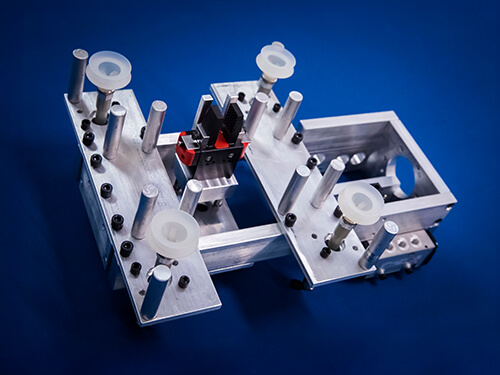

Our customers also enjoy the benefit of Convertible Tooling. One of the first steps we take when developing any new injection molding design project is Stage Tooling. This involves assessing the feasibility of building prototype tooling that converts to production tooling. This eliminates redundant tooling investment and further reduces lead-time.

We have FEA engineers on staff to aid you in optimizing the design of your injection molded parts to maximize performance while driving cost out.

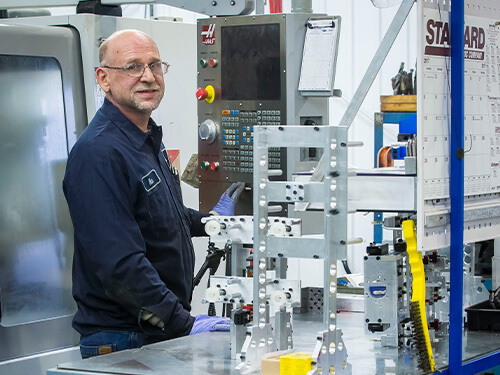

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields