Regency

BLOW MOLDING DESIGN & ENGINEERING

Our design and engineering team is committed to helping you achieve shorter lead times, lower costs, and higher quality products through the power of simulation software, in-house tooling, and rapid prototyping.

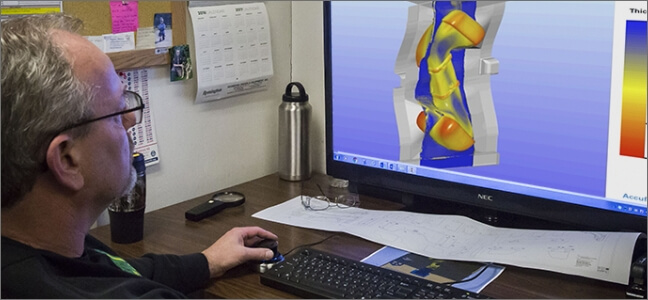

SIMULATION SOFTWARE TO ELIMINATE GUESSWORK

We start nearly every project running a CAD model of your part through our blow molding simulation software. This allows us to identify problem areas and optimize your part design for the desired results.

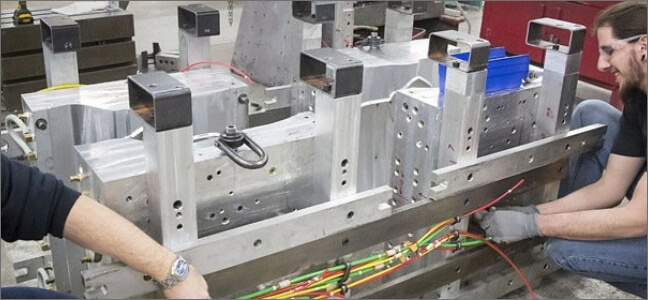

IN-HOUSE TOOLING TO REDUCE LEAD-TIMES

From the very beginning, our customers enjoy the advantage of a 2-4 week lead-time reduction for tooling as most prototype and trim/fabrication tooling is built in-house.

Rapid Blow Mold Prototyping

Speed is everything.

We have the in-house resources to produce a prototype for appearance evaluation and physical testing in four weeks or less. Better yet, our prototype tooling is made from low-cost aluminum that converts into production tooling and utilizes inserts for areas of uncertainty that may need to be modified or replaced. This reduces overall development and re-tooling costs.

Wherever You’re Located, We’re Here to Help

17 strategic locations in North America to meet the needs of our diverse customer base.

INTRO TO BLOW MOLDING DESIGN

If you’re new to blow molding and don’t know where to start, then our free Blow Mold Design Guide is for you! It will provide you with basic design guidelines for the injection, stretch, and extrusion blow molding methods so you can determine if this process is right for you.

Insights

Get to know us. Get in touch today.

We have the resources to meet any part or production challenge. Let’s talk about what that means for you.

"*" indicates required fields