GPMI, CT

The Market

AUTOMOTIVE FORGER

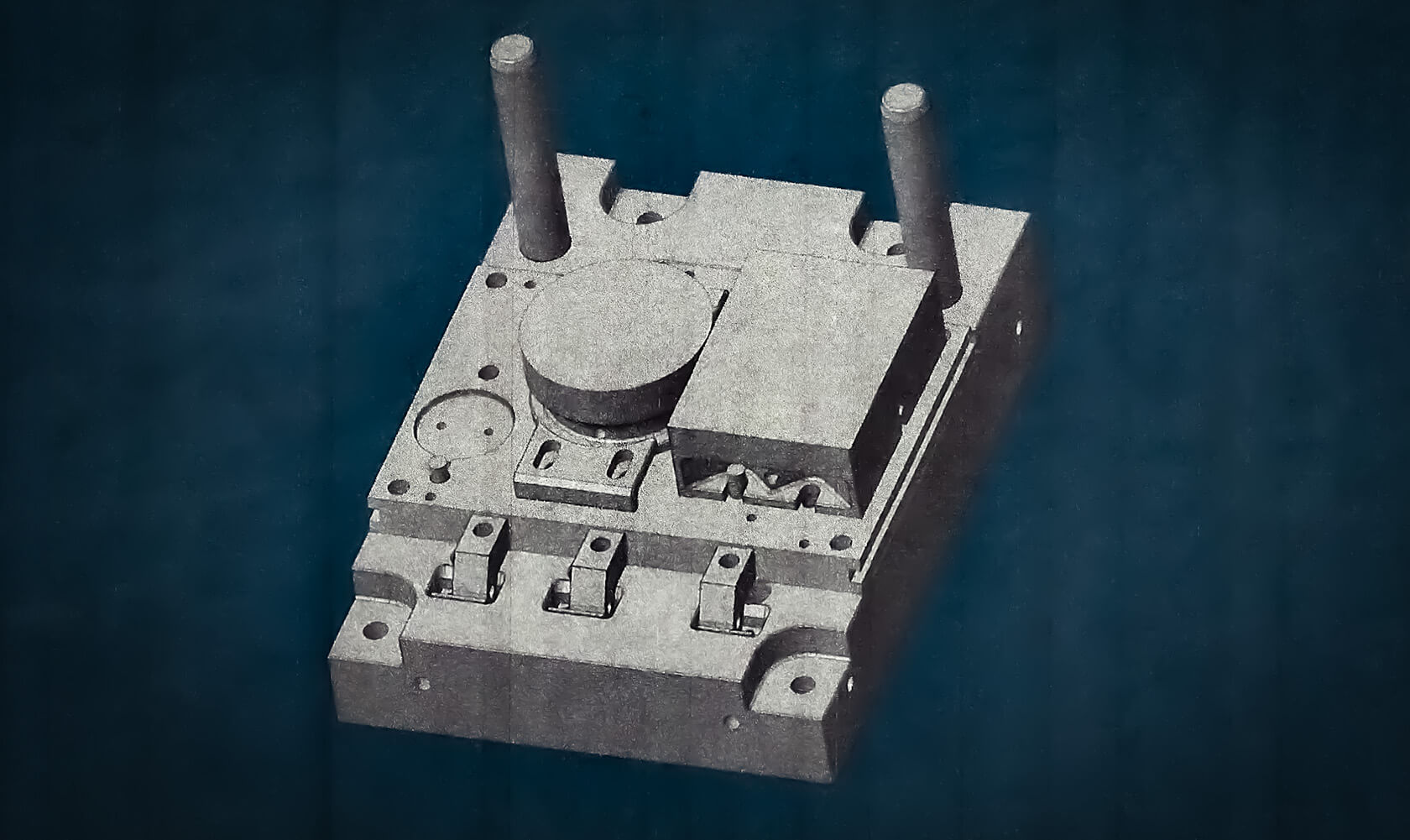

A large commercial forger producing front end constant velocity joints (CVJs) for the automotive industry.

The Challenge

A BATTLE FOR A COMPETITIVE EDGE

Due to increasingly competitive market conditions, the forger was seeking cost improvements from its suppliers to address tightening cost requirements from their customers.

The solution

LEAN PROCESS OVERHAUL AND DESIGN INNOVATIONS

We took the challenge to our Lean Process Improvement Team and analyzed every step of the die manufacturing process in search of areas to remove waste. By employing some specialized workholding tooling, the team was able to eliminate one soft-state operation.

The team also formulated a design modification that would allow elimination of two additional steps in the grinding operation as well as reducing the amount of stock to be removed. Working with the forger’s engineering team, the design modifications were approved and implemented.

The Results

SAVINGS SURGE

Ultimately, we were able to offer a 28% price reduction on a large family of die types, saving over $251,500 per year.

REDUCING THE COST OF YOUR FORGING PROCESS

We’ve spent decades helping forgers across the country enhance tool performance and improve operational efficiency, and we want to help you, too. Learn how to eliminate wasted time, money and other precious resources in our free e-book written by experts, for experts.