Regency

The Market

TIER 1 FLUID MANAGEMENT SOLUTIONS SUPPLIER

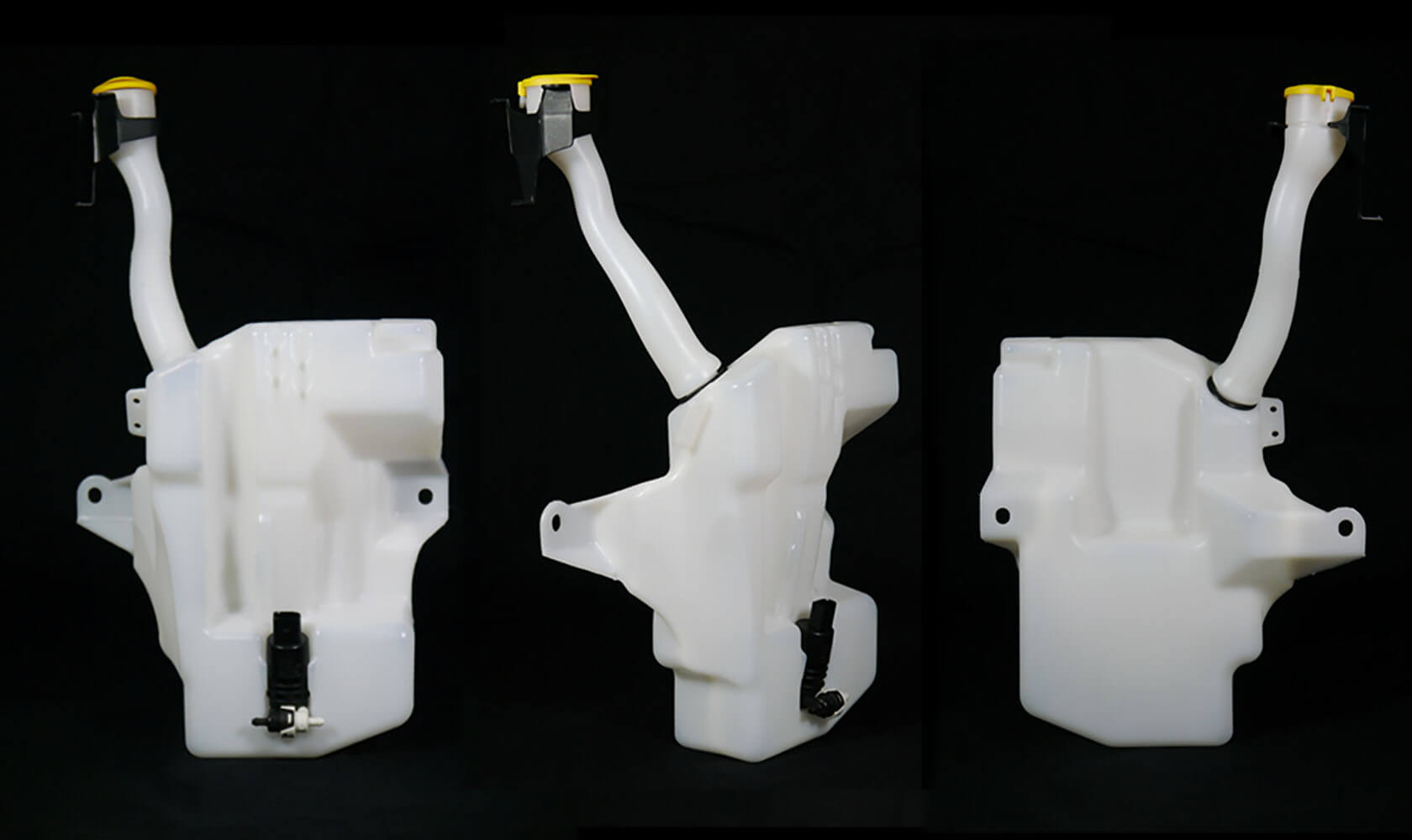

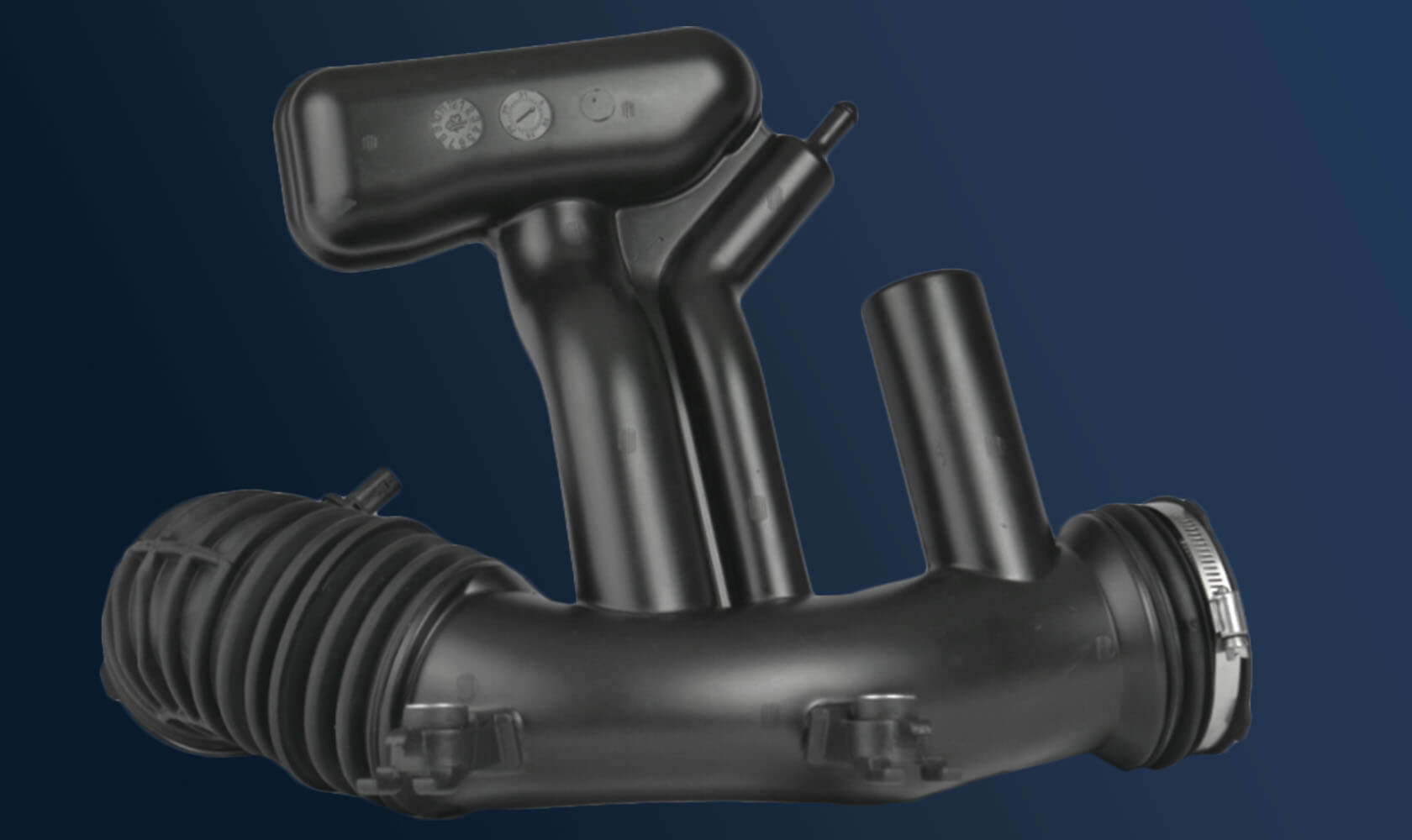

The customer is a Tier 1 supplier of custom fluid management solutions – including DEF tanks – to heavy-duty vehicles, machines, and equipment for the construction, agriculture, transportation, and aerospace industries.

The Challenge

SUPPLY CHAIN INEFFICIENCY: SCALING TO MEET HIGH-VOLUME PRODUCTION NEEDS

The customer was overburdened by sourcing six different rotomolding suppliers to meet their annual DEF tank production volumes. Aware of the inefficiencies and risks associated with this sourcing model, the customer sought to rationalize their supply chain to two or fewer suppliers. One problem – all six rotomolders were at capacity. The process they’d been using from the beginning couldn’t scale to the customer’s high-volume production needs.

The customer had looked into blow molding as an alternative manufacturing method for high volumes, but couldn’t justify the higher tooling costs. That is, until they met with our technical blow molding experts.

The solution

A SCALABLE MANUFACTURING METHOD AND SUPPLIER CONSOLIDATION

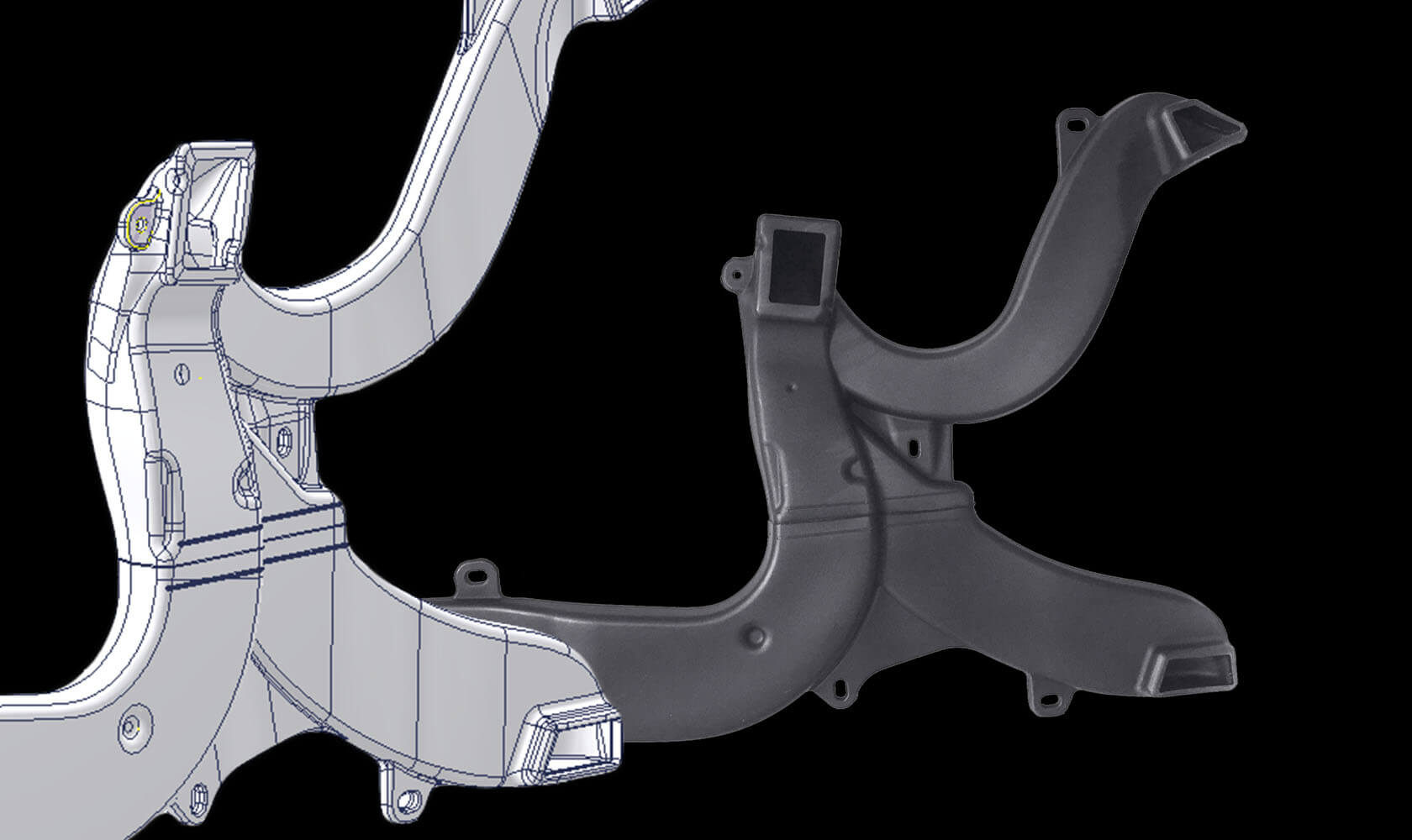

Drawing from over four decades of blow molding design, engineering, and manufacturing experience, our team worked with the customer to enhance the DEF tank design to be compatible with the blow molding manufacturing process. Coupled with our ability to design and build all tooling in-house, the customer now had a design in-hand that would see tooling payback in one year or less – in other words, the tooling would literally pay for itself in one year’s time.

The Result

A SINGLE, RELIABLE SOURCE: MEETING NEEDS WITH A LOWER COST SOLUTION

The customer now has a single scalable source for DEF tanks that meet all production and performance requirements at a 37% reduction in piece price.

| Cost-Drivers | Roto Molding | Blow Molding |

| Tooling | $150,000 / yr | $200,000 / lifetime |

| Production Rate | 2 parts / hr | 70 parts / hr |

| Piece Price | $35 / part | $22 / part |

BLOW MOLDING DESIGN GUIDE

Are you new to blow molding and don’t know where to start with your part design? Then our Blow Molding Design Guide is for you! Created by engineers, for engineers, this guide is the ultimate starting point to kick off a successful product design for the blow molding process.