Regency

The Market

TIER 1 AUTOMOTIVE SUPPLIER

The customer is a Tier I supplier to automotive OEMs, specializing in air induction systems. While the customer is an expert in air filtration and air boxes, they rely on Tier II suppliers for other system components such as clean and dirty air ducts.

The Challenge

OVERCOMING SUPPLIER INEFFICIENCIES TO MEET OEM COMMITMENTS

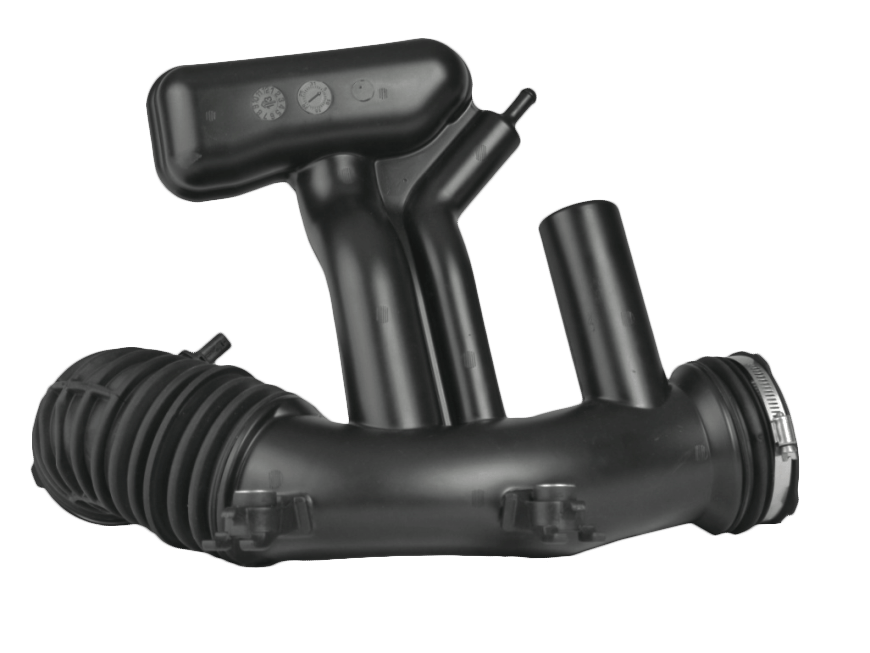

In manufacturing an air duct for the Jeep Wrangler, the customer was dealing with suppliers who said they could blow mold technical products at automotive quality standards, but when it came time to perform, those suppliers struggled to produce parts to print, repeatably. This led to unmet development lead-time commitments, which in turn compromised the customer’s relationship and reputation with the OEM.

The customer had to find an alternative supplier – one with DFMA experience that could deliver on a tight timeline. That’s when we stepped in and co-designed a solution with the customer.

The solution

COLLABORATIVE DESIGN AND RAPID DEVELOPMENT

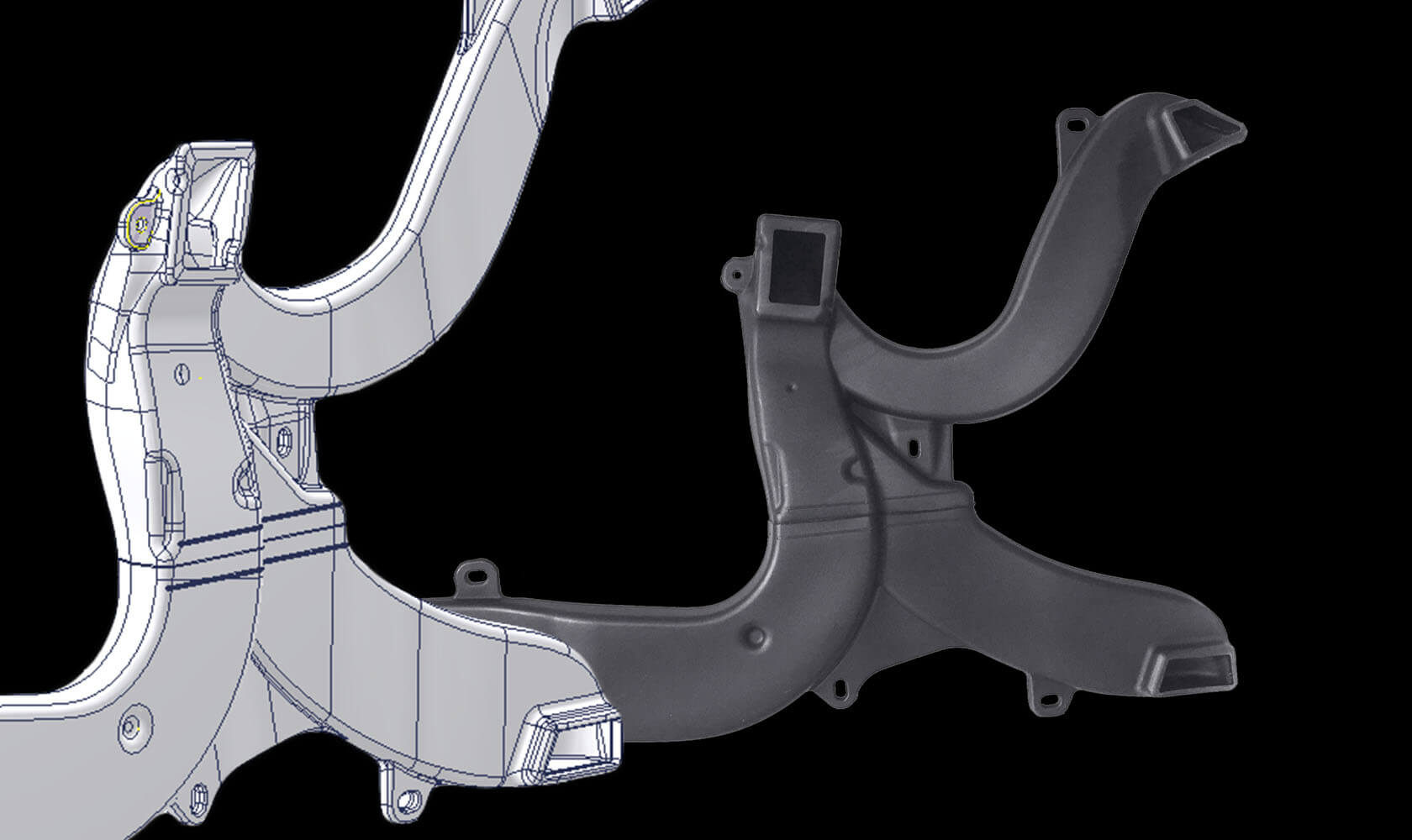

The customer reached out to us after learning that we have over 40 years of experience in blow molding for the automotive industry. After meeting with the customer to understand the OEM’s requirements, we co-engineered the CAD components with the customer. We then designed components for the welding process that optimized the joining process for repeatability.

Inevitably, changes in the engine environment required changes to the part geometry and packaging. Fortunately, we’re equipped with an in-house tooling department which allowed us to respond quickly and keep the program on schedule.

The Result

TIMELY DELIVERY, AN ENHANCED REPUTATION, AND A NEW, RELIABLE SUPPLIER FOR AIR DUCTS

The part was delivered to Jeep Wrangler on time and met all performance requirements, which greatly improved the customer’s reputation. As a result, the customer and the OEM now have a reliable source for their air intake assemblies.

BLOW MOLDING DESIGN GUIDE

Are you new to blow molding and don’t know where to start with your part design? Then our Blow Molding Design Guide is for you! Created by engineers, for engineers, this guide is the ultimate starting point to kick off a successful product design for the blow molding process.